Ridge Vent vs Box Vents for Metal Roofs in Central Florida, How to Size Intake and Exhaust So It Actually Works

If your attic can't breathe, your home pays the price. In Central Florida, heat loads are high, humidity is constant, and a metal roof can highlight ventilation mistakes fast. You'll feel it as higher cooling bills, sweaty ductwork, and that "why is my attic so sticky?" feeling.

The fix isn't "add more vents." The fix is metal roof ventilation that moves air in a controlled path: in low at the soffits, out high at the ridge (or near it), with intake and exhaust that actually match.

Below is a practical way to choose ridge vent vs box vents for a metal roof, then size intake and exhaust using the numbers on the vent packaging (NFVA), not guesswork.

What "working ventilation" means under Florida code (and in real life)

Florida code language centers on net free ventilation area (NFVA). That's the open area air can really move through after screens and louvers. In a vented attic, the baseline target is commonly:

- 1/150 rule : Total NFVA (sq ft) = Attic floor area (sq ft) / 150

- 1/300 option : Allowed in some assemblies when certain conditions are met (for example, balanced distribution and vapor retarder details). Always confirm what your inspector expects.

You can read the current code chapter for vents in the 2023 Florida Building Code, Residential, Chapter 31.

Code also cares about keeping critters out. Vent openings generally need to fall in a "small but breathable" range, and larger openings require corrosion-resistant screening. That matters in Florida, where wasps, palmetto bugs, and wind-driven debris are part of the deal.

Airflow also needs a clear path. If insulation blocks the soffit edge, the attic can't pull in enough air. That's why baffling at the eaves matters, especially after an insulation top-off.

For a metal-roof-focused overview of balanced airflow (and why "exhaust bigger than intake" backfires), this proper metal roof ventilation guide is a solid refresher.

A vented attic works like a chimney. If the "makeup air" (intake) is choked, the chimney won't draft, no matter how big the exhaust looks.

Ridge vents on metal roofs: best airflow with fewer leak points (when the ridge is right)

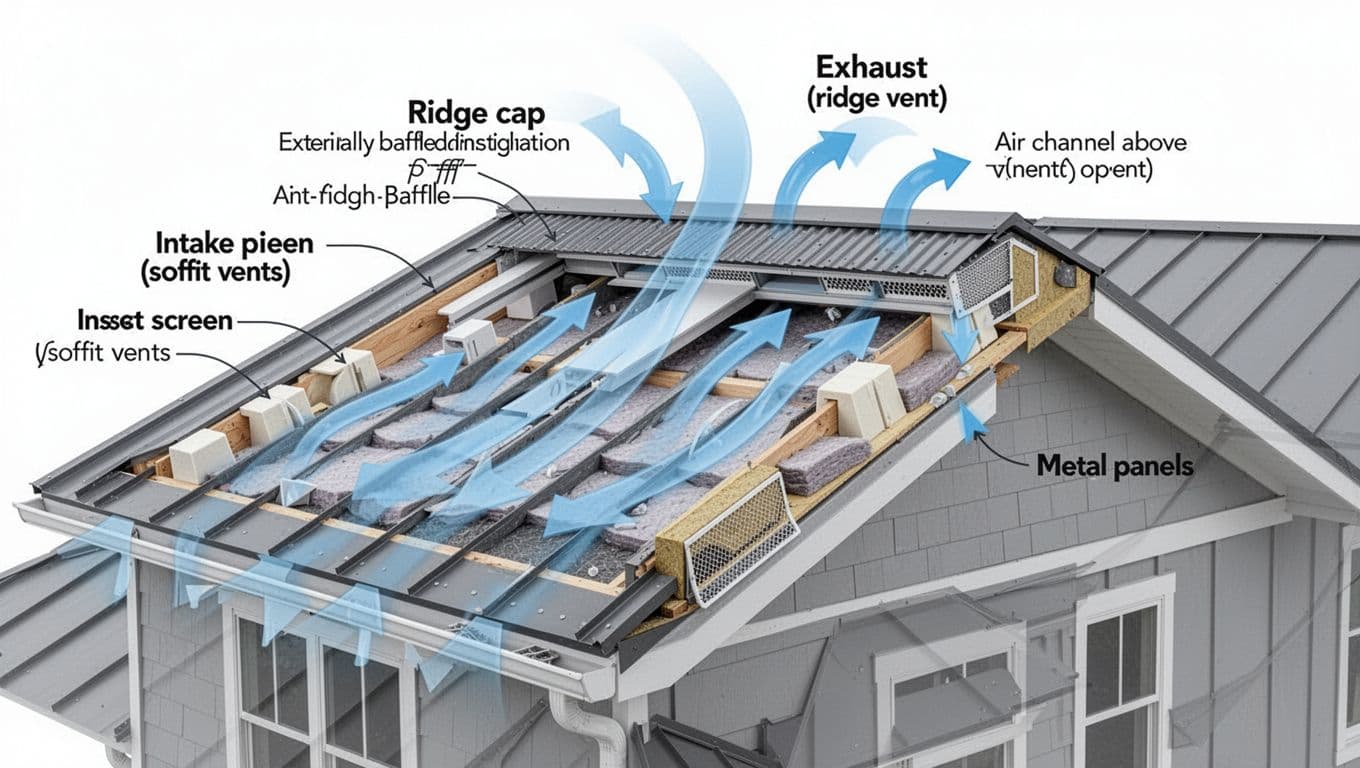

Cross-section showing soffit intake feeding a continuous ridge exhaust path, created with AI.

Cross-section showing soffit intake feeding a continuous ridge exhaust path, created with AI.

A ridge vent is "continuous exhaust." Instead of a few exit points, you get one long outlet at the top of the roof. On many Central Florida homes, that creates smoother airflow and fewer hot pockets.

Why ridge vents often win on metal:

- Fewer roof penetrations than box vents, which means fewer long-term leak risks.

- Even exhaust along the peak, which helps pull air across the whole attic.

- Cleaner look from the ground.

Florida weather detail that matters: choose an externally baffled ridge vent when possible. In strong gusts and sideways rain, baffles help resist wind-driven water entry while still exhausting air.

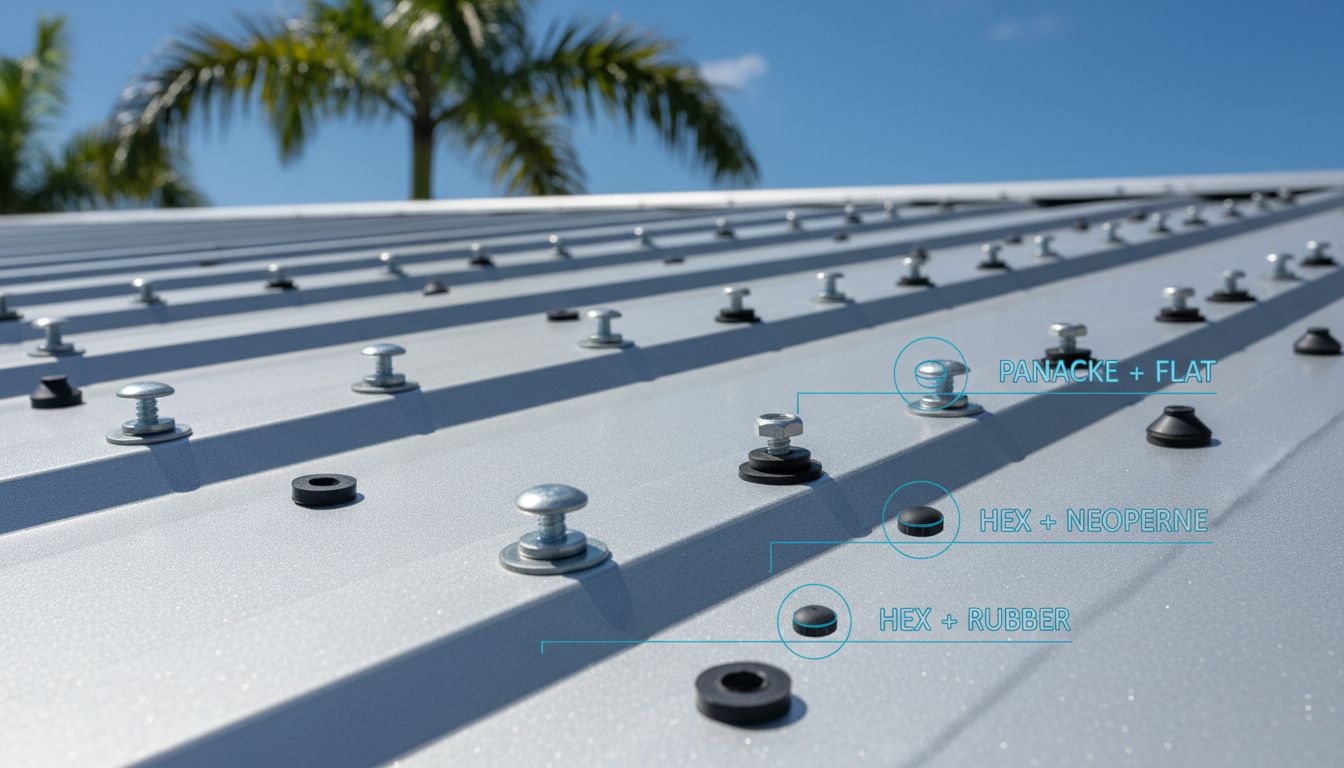

Also, ridge vent performance depends on ridge cap details. On metal roofs, you want the ridge cap to shed water like the rest of the system. That means correct overlaps, fastener placement, and closures that don't create a water path. A vented foam closure designed for ridge ventilation can help, while still fitting panel ribs. For examples of ridge vent and closure options used on metal panels, see metal roof ridge vents and accessories.

Even if you're in Central Florida (not the HVHZ counties), hurricane rain patterns still matter. In HVHZ areas, ridge vents have extra testing and approval requirements. A good reference point is this code snippet on ridge vent testing for wind-driven rain: ridge vents testing requirement (FBC Building). It's a helpful reminder to stick with approved systems and documented details.

When ridge vents aren't a great fit on metal roofs:

- Very short ridges (you can't get enough NFVA).

- Complex hips and ridges with no long, continuous peak.

- Roof designs where a "ridge" is interrupted by dormers or raised sections.

- Cathedral or compact roof assemblies where there's no vented attic airspace (these are often designed as unvented assemblies, and adding vents can create moisture problems).

If you're planning a new metal roof and want the ventilation, underlayment, and trim sequence to line up, this metal roofing ventilation best practices guide helps you think through timing and details.

Box vents on metal roofs: flexible placement, but more penetrations to protect

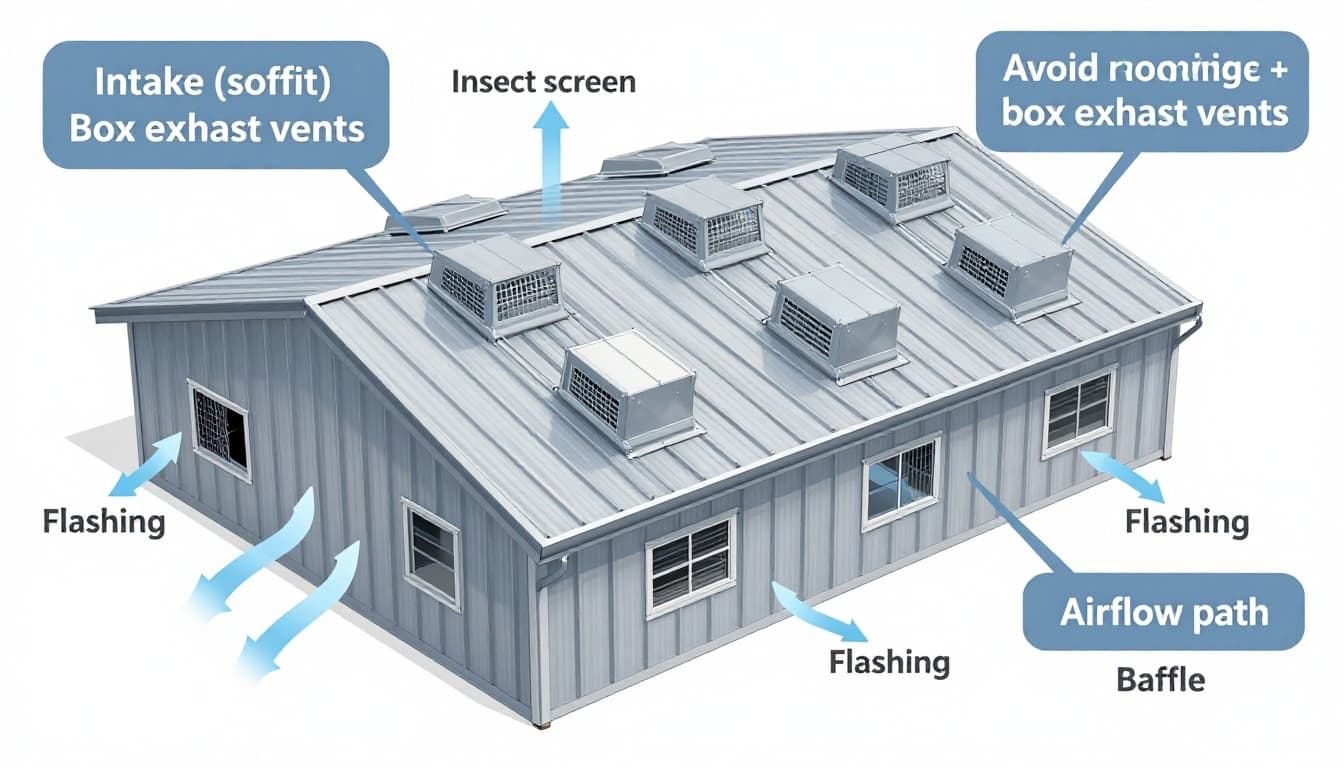

Cross-section showing soffit intake feeding multiple box vents near the ridge, created with AI.

Cross-section showing soffit intake feeding multiple box vents near the ridge, created with AI.

Box vents (sometimes called static vents) can work well when a ridge vent won't. For example, a hip roof with short ridge segments might not have enough linear ridge to meet the exhaust NFVA target, so several box vents near the peak can do the job.

Still, every box vent is a roof opening. On a metal roof, that means:

- Proper flashing compatible with your panel profile

- Correct fasteners and sealant placement

- Clean cuts that don't leave sharp burrs

- Insect screening that doesn't choke airflow

In hurricane season, box vents also sit right in the "wind and rain" zone near the roof peak. Good product selection and careful flashing are what keep them from becoming water entry points.

Don't mix ridge vent and box vents as exhaust on the same attic. It usually short-circuits the system. Air exits the closest opening instead of sweeping the whole attic. If you're switching from box vents to ridge vent, decommission the old exhaust vents (patch and re-panel correctly) so you end up with one clear exhaust strategy.

Mixing exhaust types isn't "extra ventilation." It's often a broken airflow path.

How to size intake and exhaust (NFVA) with a worked Central Florida example

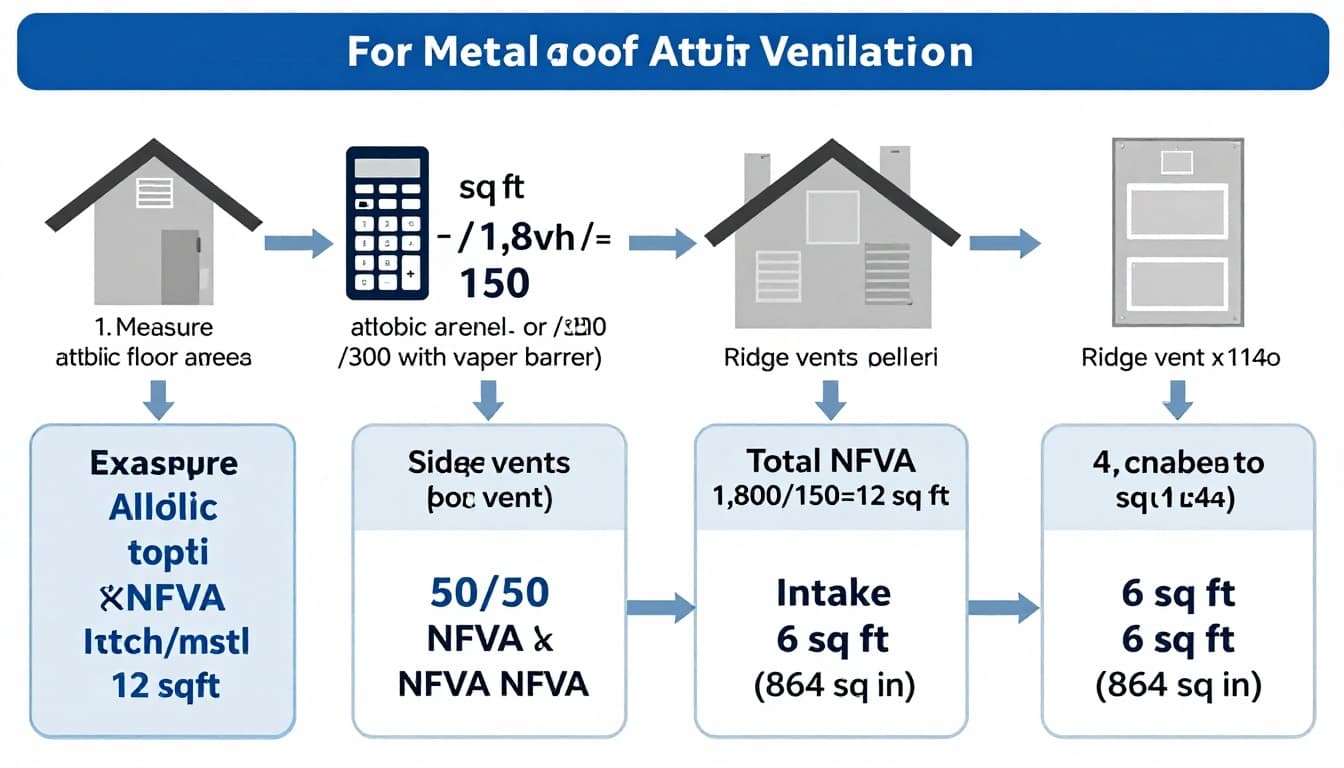

Sizing workflow for NFVA and a sample calculation, created with AI.

Sizing workflow for NFVA and a sample calculation, created with AI.

Here's the math that keeps ventilation from turning into guesswork.

Step 1: Calculate total NFVA needed

Example attic floor area: 1,800 sq ft

Using 1/150:

- Total NFVA (sq ft) = 1,800 / 150 = 12 sq ft

- Convert to square inches: 12 * 144 = 1,728 sq in

Step 2: Split between intake and exhaust (balanced system)

A simple target is a 50/50 split, with intake slightly higher if you can.

- Exhaust target = 1,728 / 2 = 864 sq in

- Intake target = 864 sq in (or a bit more, like 900 sq in, if layout allows)

Why "intake at least equal to exhaust" matters:

If exhaust NFVA is bigger than intake, the attic still needs makeup air. It will pull from the easiest place. That can mean pulling air backward

through exhaust vents, pulling conditioned air from the house through ceiling leaks, or pulling humid air from odd gaps. As a result, you get weaker flow across the attic and more moisture risk.

If you've ever seen "condensation that looks like a leak," ventilation balance is often part of the story. This metal roof ventilation to prevent condensation breaks down common Florida causes.

Step 3: Size ridge vent exhaust (example) or box vent exhaust (example)

Use the NFVA rating from the product's specs or packaging. If you need a source for how product approvals document vent products, this Florida submittal is one example: Florida product approval ventilation document (PDF).

Ridge vent example (use your vent's NFVA):

If a ridge vent provides 18 sq in NFVA per linear foot

, then:

- Ridge vent length needed = 864 / 18 = 48 linear feet

If your ridge is only 20 feet long, ridge vent alone can't hit the exhaust target. That's when box vents or another design may make more sense.

Box vent example (use your vent's NFVA):

If one box vent provides 50 sq in NFVA

, then:

- Box vents needed = 864 / 50 = 17.3 , round up to 18 vents

That number surprises people, which is why many "a few box vents" installs underperform. In real projects, contractors often combine multiple intake styles and choose higher-NFVA vents to reduce the total count, while staying within layout and manufacturer rules.

Bottom line for Central Florida metal roofs

Ridge vents usually deliver the cleanest airflow on a metal roof, with fewer leak points, as long as you have enough continuous ridge length and the right ridge cap and closure details. Box vents can still work when the roof shape won't support ridge vent sizing, but you must treat every penetration like a flashing detail that has to survive hurricane rain.

Before you add vents, calculate NFVA and match intake to exhaust . When those numbers line up, the attic finally starts acting like it should, hot air rises, fresh air replaces it, and your metal roof system performs better year after year.