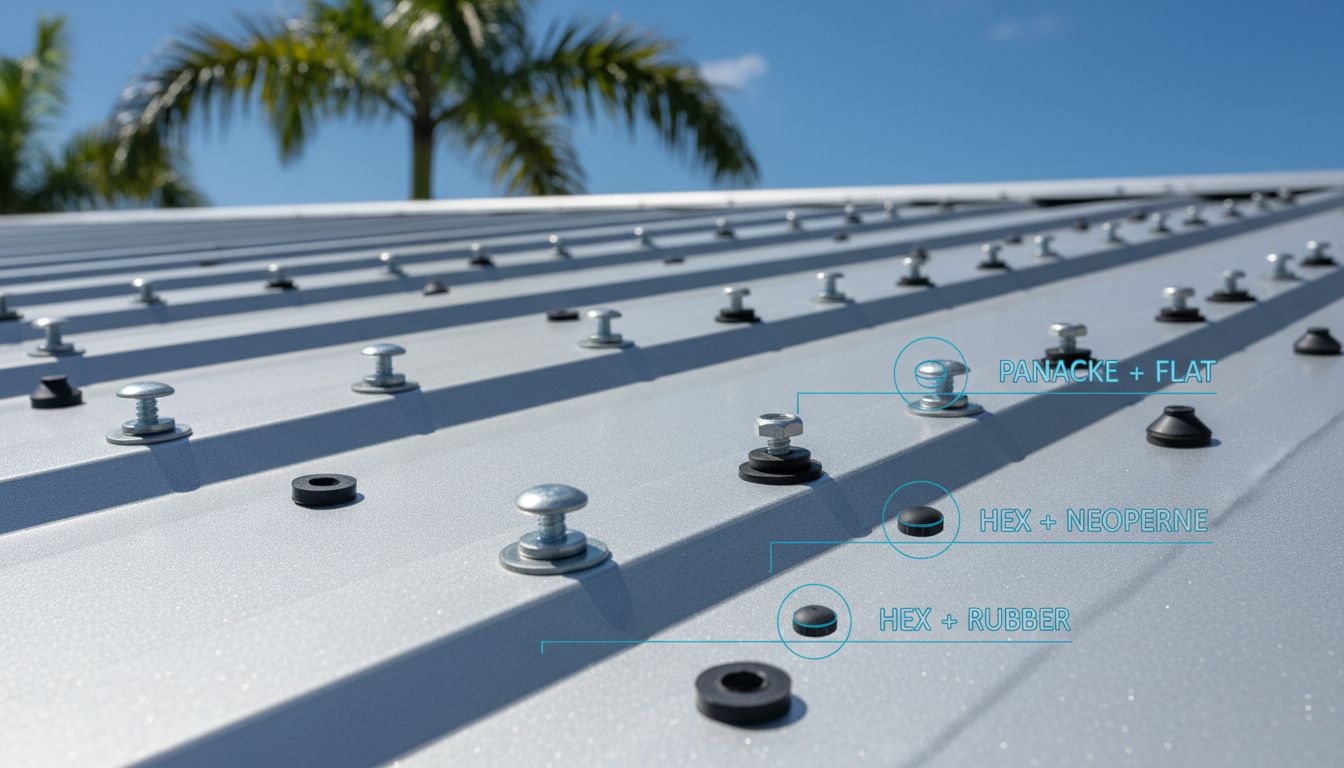

Metal Roof Screw Guide for Central Florida, Pancake Head vs. Hex Head, Washer Types, and Where Each One Belongs

If a metal roof is the shield, metal roof screws are the stitches that hold it together. In Central Florida, that stitching takes a beating from daily heat swings, long stretches of humidity, and wind events that don’t always give you a warning.

The tricky part is that “roofing screws” aren’t one-size-fits-all. A screw that’s perfect for fastening panels can be the wrong choice for trim. The right washer can seal for decades, while the wrong one can split or dry out and start a slow leak you won’t notice until the decking stains.

This guide breaks down pancake head vs. hex head, common washer types, and a practical “where it goes” map you can use on real jobs.

Central Florida fastener basics: wind, water, and code reality

Metal roofing in Florida isn’t just about keeping rain out. It’s also about staying put when uplift loads climb at roof edges and corners. That’s why fastener type and spacing have to match the approved roof system you’re installing.

A few practical, non-negotiable points:

- Follow the tested assembly. Your panel profile, substrate (wood deck vs. steel purlins), and fastener pattern should match the Florida Product Approval for the roof system, not “what we’ve always done.” You can see how detailed these approvals get in example documents on the state site, like this Florida Product Approval metal roof listing PDF.

- Know the code edition in play. As of February 2026, most of Central Florida is using the 2023 Florida Building Code (8th edition). For a readable view into roof assembly requirements, see FBC Residential Chapter 9 on roof assemblies. Local amendments can still apply, so check your county or city building department if something seems inconsistent.

- Corrosion is local. Orlando and Ocala aren’t Cocoa Beach. If you’re near salt exposure, treat it like a different job: higher corrosion resistance, more attention to washer material, and no “mix and match” metals.

For a deeper fastener overview from the metal building world (and a good reminder that fasteners are part of the engineered system), bookmark Metal Construction News guidance on choosing fasteners.

If you want a broader fastener primer tailored to metal panels, this internal resource is a solid companion: selecting screws for your metal roofing.

Pancake head vs. hex head: what changes, and why it matters

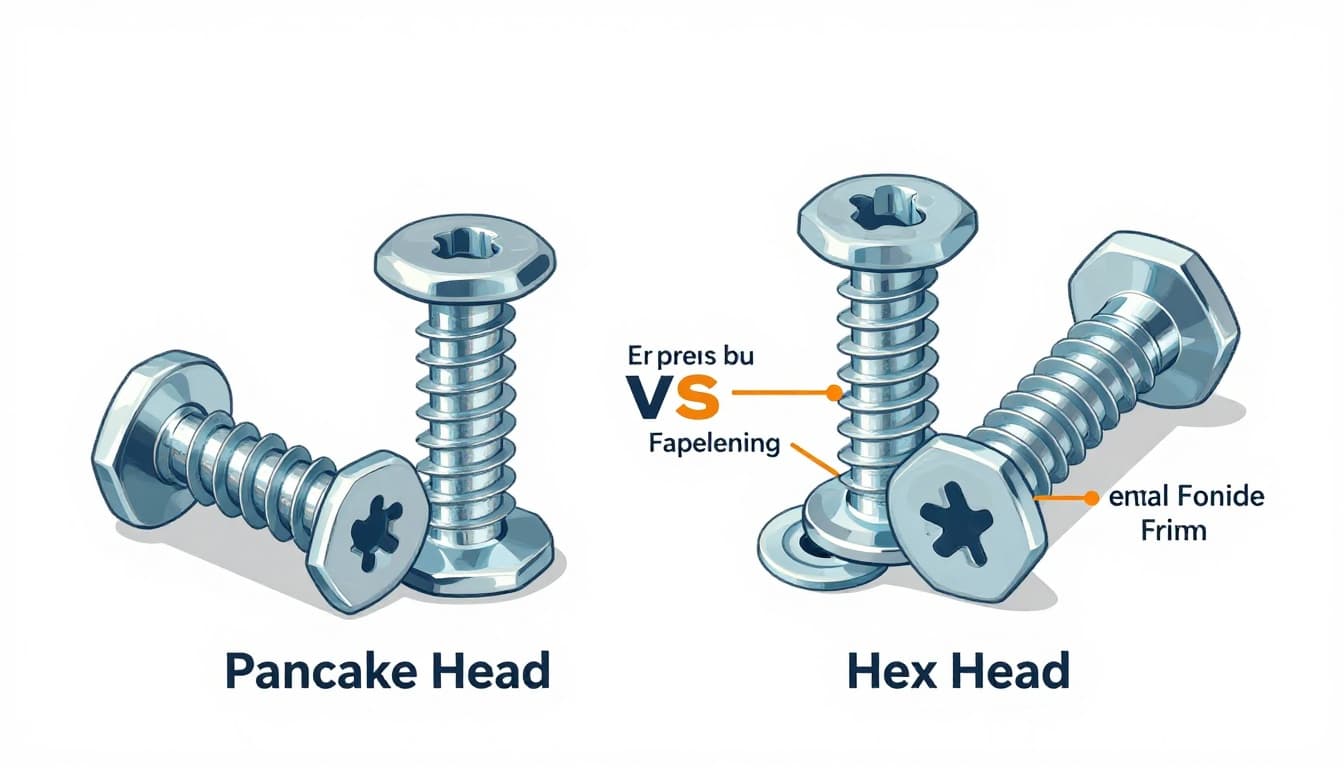

Side-by-side head style comparison to help match the screw to the task, created with AI.

Side-by-side head style comparison to help match the screw to the task, created with AI.

Think of the screw head as the “clamp.” Two screws can be the same length and diameter, but the head shape changes how it sits, how it spreads load, and how it seals.

Hex head (hex washer head): the workhorse for panels

Hex head screws are common on through-fastened metal roofing because they’re built for torque and production speed. They’re usually paired with a sealing washer under the head (often bonded EPDM).

Use hex head screws when:

- You’re fastening panels to structure (wood decking, purlins, girts, or framing as designed).

- You need strong pull-down without stripping the drive recess.

- You want a head that’s easy to run straight with a nut driver.

The risk: hex heads make it easy to overdrive with a strong impact. Over-torque can dish the panel, split the washer, or “spin out” the threads in wood.

Pancake head: low-profile control for laps and trim

Pancake head screws sit flatter and are often used where a bulky head would interfere with overlapping metal. Many are used as stitching screws at sidelaps or for certain trim and accessory connections (depending on the panel system).

Use pancake head screws when:

- You’re stitching sidelaps (panel-to-panel, not panel-to-framing).

- You need a lower-profile head under a cap or overlap.

- You want better bearing surface than a small pan head in thin sheet-to-sheet connections.

The risk: pancake heads are not automatically “better for everything.” If you use a short stitch screw where you actually needed structure engagement, you’ll get uplift problems and elongated holes.

Quick reference: head choice by task

| Task on the roof | Head style that’s commonly used | Why |

|---|---|---|

| Panel-to-wood deck or purlin fastening | Hex head | Torque-friendly, strong clamp load |

| Sidelap stitch (panel-to-panel) | Pancake head | Low profile, clean overlap |

| Trim attachment (varies by detail) | Often hex or pancake | Depends on overlap clearance and substrate |

For long-term durability, pair good head selection with long-life fasteners that match the roof’s service life. (More on that here: why durable screws for metal roofing matter.)

Washer types: EPDM vs “rubber,” metal-only, and oversized

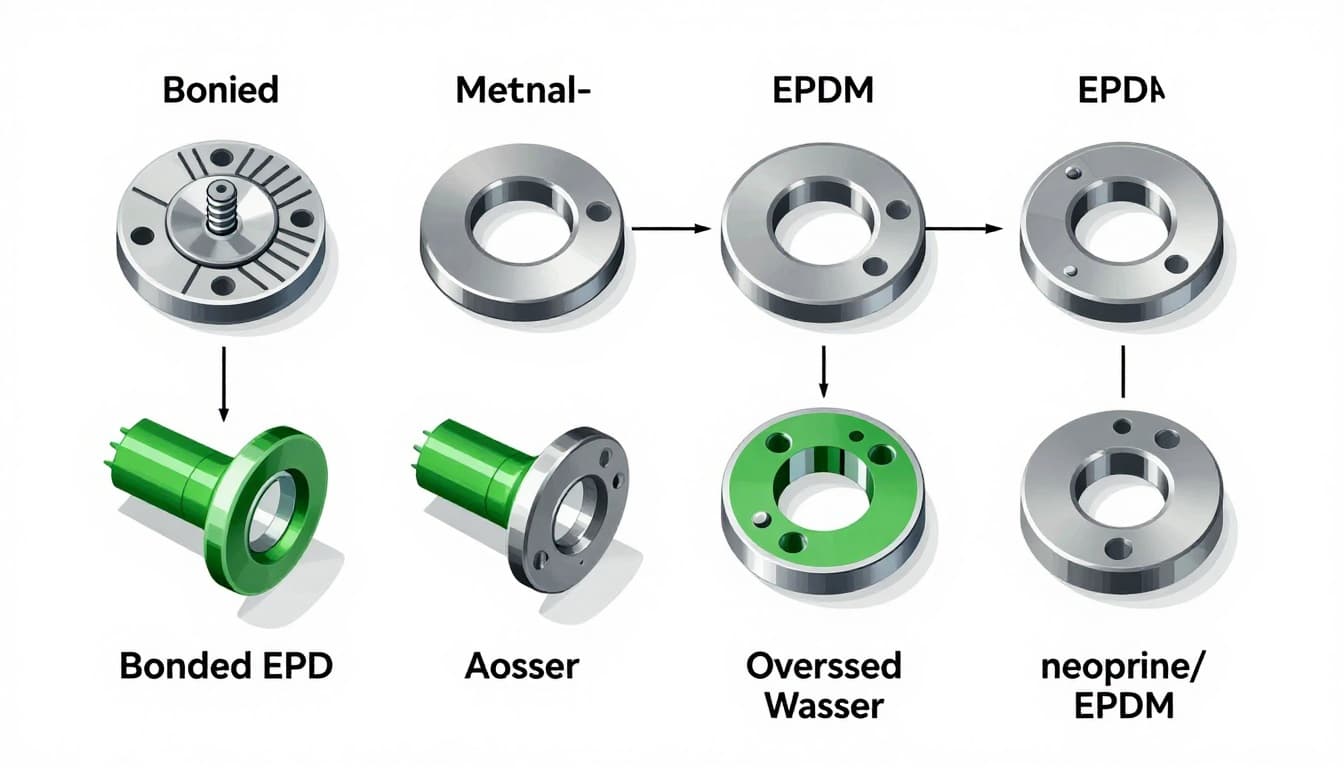

Washer cross-sections showing how sealing happens (and how it fails), created with AI.

Washer cross-sections showing how sealing happens (and how it fails), created with AI.

A washer on a roofing screw is like the gasket on a water bottle cap. If it’s too loose, it leaks. If it’s crushed, it cracks. In Central Florida, UV and heat punish cheap materials fast.

Bonded EPDM sealing washers (most common for exposed fasteners)

A bonded EPDM washer is typically EPDM rubber bonded to a metal backing. The metal spreads load, the EPDM makes the seal.

What “right tight” looks like:

- The washer is evenly compressed , not tilted.

- EPDM slightly “squeezes” to the edge, but doesn’t bulge wildly.

- No splits, no puckering, no exposed bare metal gouging the panel.

Neoprene vs EPDM

You’ll hear both terms in the field. The big takeaway for Florida is simple: use the washer material specified for the screw and roof system , and don’t downgrade to generic rubber. EPDM is widely used on roofing screws because it holds up well outdoors.

Metal-only washers

Metal-only washers don’t seal water on their own. They’re used in specific details when the waterproofing comes from another layer (butyl tape, sealant, overlapping geometry, or concealed fastening).

Oversized washers and oversized screws (retrofit friendly)

When you’re re-fastening a roof with worn holes, oversized options can help restore holding power, but they need to be part of a thought-out repair. If the substrate is rotten or the purlin is too thin for the selected screw, “bigger” isn’t a fix.

Washer selection by exposure

| Exposure and location | Washer choice that usually fits | Notes |

|---|---|---|

| Open, exposed fasteners on panels and trim | Bonded EPDM sealing washer | Standard choice for watertight seal |

| High UV, high heat surfaces | High-quality EPDM | Watch for over-compression during install |

| Retrofit with slightly wallowed holes | Oversized washer (or oversized screw as designed) | Confirm substrate integrity first |

| Sheet-to-sheet laps with sealant | May be washered or metal-only (detail-specific) | Follow manufacturer detail and approvals |

Where each screw belongs: a placement map you can build by

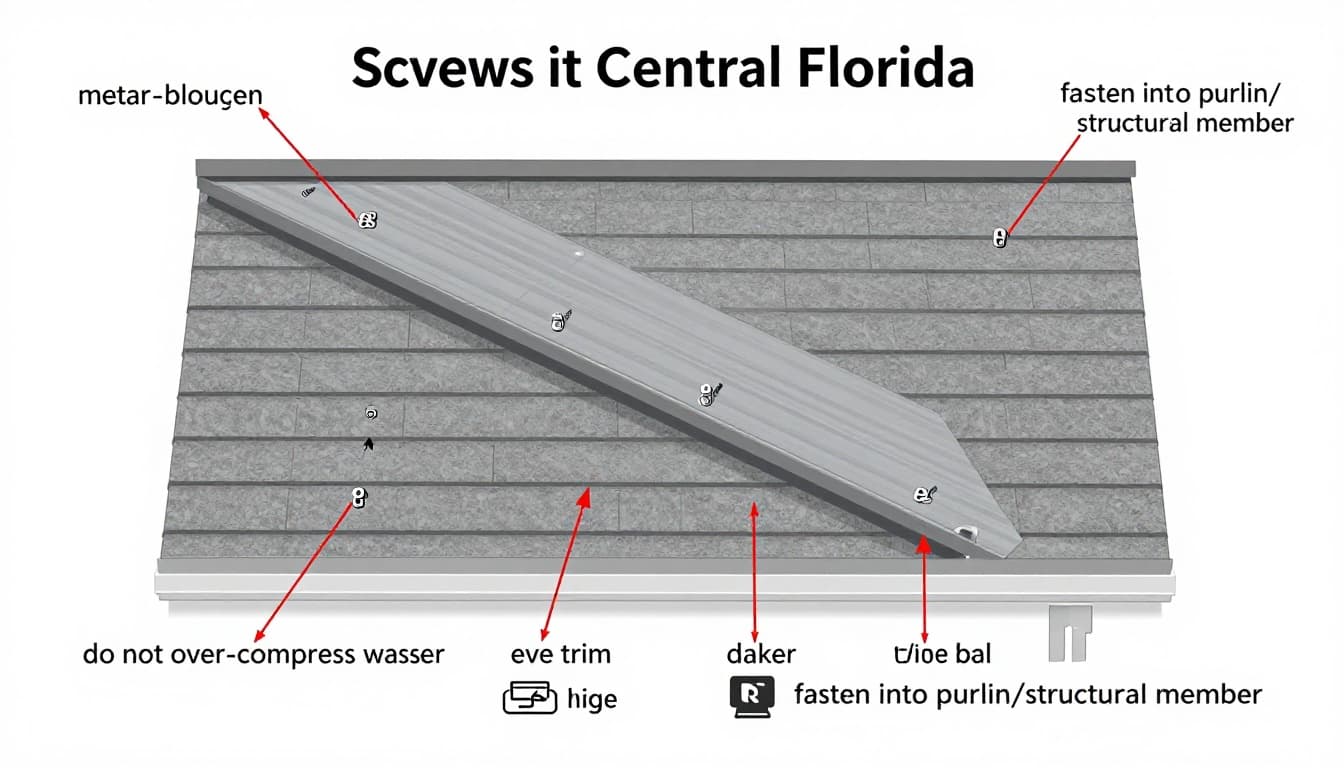

Common fastener locations shown on a roof section for quick visual planning, created with AI.

Common fastener locations shown on a roof section for quick visual planning, created with AI.

If you only remember one rule, make it this: stitch screws are not structural fasteners . They clamp metal to metal. Structural screws must bite into wood or steel framing the way the system was tested.

Fastener selection by roof location (quick table)

| Roof area | Typical fastener job | Common screw style | Install notes |

|---|---|---|---|

| Panel field (main runs) | Panel-to-structure fastening | Hex head with bonded EPDM | Drive straight, washer evenly compressed |

| Edges and corners | Higher uplift zones | Hex head with bonded EPDM | Spacing often tight per approved layout |

| Sidelaps | Panel-to-panel stitch | Pancake head (often) | Don’t substitute long structural screws |

| Ridge cap and hip cap | Trim-to-panel or trim-to-structure (detail-specific) | Hex or pancake, usually washered | Use closure and sealant per detail |

| Eave trim and rake trim | Edge metal attachment | Often washered screws | Avoid overdriving into thin metal |

| Pipe boots and penetrations | Flashing clamp and seal | Washered screws per boot detail | Don’t mix incompatible sealants and washers |

Screw length and penetration: what “enough bite” means

Length is not about “longer is safer.” It’s about correct engagement.

A good rule of thumb is that the screw should fully engage the structural member (wood or steel) with meaningful thread bite. Many manufacturer details call for roughly 1 inch of embedment into wood, but your exact requirement comes from the approved assembly and substrate thickness.

Also pay attention to point type:

- Self-drilling points are common when fastening into steel framing.

- Sharp points are common for wood substrates.

Don’t mix metals without thinking

Galvanic corrosion is real in Florida moisture. Avoid pairing dissimilar metals in a way that turns your roof into a battery (example: using an incompatible fastener material against certain panels or trim). Match fastener material and coating to the panel and the environment, especially near the coast.

Common mistakes in Central Florida (and easy fixes)

| What goes wrong | What you’ll see later | Practical fix |

|---|---|---|

| Over-compressed washer | Split EPDM, rust ring, slow leak | Replace fastener, re-drive to proper compression |

| Under-driven screw | Washer not seated, screw backs out | Re-seat or replace, verify substrate bite |

| Using stitch screws as structural fasteners | Panels flutter, enlarged holes | Re-fastening with correct structural screws per pattern |

| Mixing short screws into thick trim stacks | Loose trim, wind noise | Use correct length for the stack-up thickness |

| Retrofit into rotten decking | “Tight today, loose tomorrow” | Repair substrate first, then re-fastener plan |

For a broader look at accessories that work with fasteners (closures, underlayment, vents), keep this handy: essential fasteners and accessories to secure metal roofs.

Conclusion

Choosing metal roof screws in Central Florida is less about preference and more about matching the fastener to the job: hex heads for structural panel attachment, pancake heads for low-profile laps and stitching, and washers that seal without getting crushed. Keep corrosion resistance front and center near salt exposure, and don’t “mix and match” screw types when you’re re-fastening. If you install the right fastener in the right place, the roof stays quiet, tight, and dry for the long haul.