How to Choose the Right Fasteners for Your Metal Roof

When it comes to installing a metal roof, the importance of choosing the right fasteners cannot be overstated. These small yet crucial components play a vital role in the overall performance, durability, and longevity of your roofing system. Selecting the appropriate fasteners for your metal roof involves understanding various factors, including the material, type, size, and environmental considerations. In this comprehensive guide, we will delve into these aspects to help you make an informed decision when selecting fasteners for your metal roof.

Understanding Fastener Materials

Galvanized Steel

Galvanized steel fasteners are coated with a layer of zinc to prevent rust and corrosion. They are suitable for environments where moisture levels are moderate but are not recommended for coastal areas where the salt content in the air is high.

Stainless Steel

Stainless steel fasteners are more resistant to corrosion than galvanized steel, making them an excellent choice for coastal regions. They are more expensive but offer superior durability and a longer lifespan.

Aluminum

Aluminum fasteners are lightweight and resistant to corrosion, especially in alkaline environments. However, they are not as strong as steel and are not recommended for areas with heavy snowfall or high winds.

Copper

Copper fasteners are often used with copper roofs due to their compatibility. They offer excellent corrosion resistance and durability but are significantly more expensive.

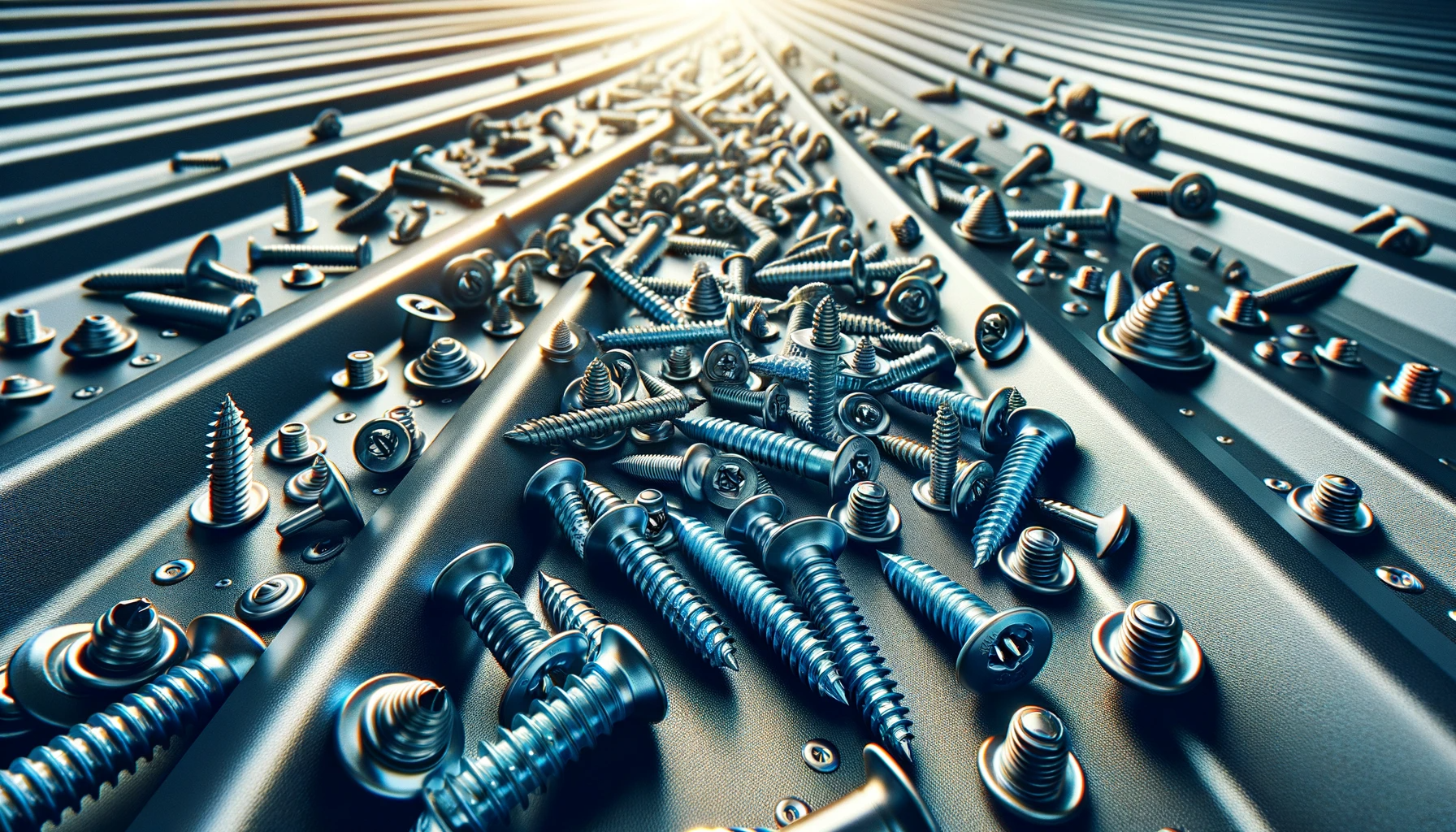

Types of Fasteners

Screws

Screws are the most common type of fastener used in metal roofing. They provide strong holding power and are available in various lengths and head types. Screws can be self-drilling, which means they have a drill point that eliminates the need for pre-drilling holes.

Nails

Nails are less commonly used in metal roofing due to their lower holding power compared to screws. However, they can be used in certain applications, such as attaching metal flashing or trim.

Rivets

Rivets are used in situations where a strong, permanent joint is required. They are especially useful in attaching metal panels to metal frames or in areas where access to the back of the panel is restricted.

Selecting the Right Size and Length

The size and length of the fasteners are critical factors in ensuring a secure metal roof installation. The length of the fastener should be chosen based on the thickness of the roofing material and any underlying materials such as insulation or wooden battens. Generally, the fastener should penetrate at least 1 inch into the purlin or support structure.

The diameter of the fastener also matters, as a larger diameter provides greater holding strength. However, it should not be so large as to cause damage to the metal panels during installation.

Environmental Considerations

The environment where the roof will be installed plays a significant role in the choice of fasteners. Coastal areas, industrial environments, or regions with high humidity require fasteners with higher corrosion resistance. In such cases, stainless steel or specially coated fasteners are the best options.

In areas with high wind speeds or frequent storms, fasteners with greater holding power and wind uplift resistance should be chosen to ensure the stability and integrity of the roofing system.

Compatibility with Metal Panels

The fastener material must be compatible with the material of the metal panels. Using incompatible materials can lead to galvanic corrosion, which occurs when two dissimilar metals are in contact in the presence of an electrolyte, such as water. For example, using copper fasteners on an aluminum roof can lead to corrosion of the aluminum panels.

Aesthetic Considerations

While functionality and performance are paramount, aesthetics also play a role in the selection of fasteners. Many fasteners come in a variety of colors, allowing them to blend seamlessly with the color of the metal panels. This creates a more visually appealing finish for the roof.

Installation Techniques

Proper installation of fasteners is as important as their selection. Fasteners should be installed perpendicular to the roof surface to ensure a watertight seal. Over-tightening can strip the fastener or deform the metal panel, while under-tightening can lead to leaks or wind uplift.

Conclusion

Selecting the right fasteners for your metal roof is a critical decision that impacts the performance, longevity, and appearance of your roof. By considering the material, type, size, environmental conditions, compatibility, and aesthetic preferences, you can ensure a secure and durable roofing system. Always consult with a professional roofing contractor to make the best choice for your specific roofing needs.

Share Our Metal Roofing News Articles

Related Posts

Florida Product Approval and Miami-Dade NOA for Metal Roofing, how to pick compliant panels and trim