Metal Roof Noise in Florida Rainstorms, What Makes It Loud and How to Quiet It Down (insulation, deck type, attic space)

Florida rain can hit like someone dumping a bucket of gravel on the roof. If you’ve got a metal roof, that sound can be cozy, or it can feel like it’s echoing through the whole house. The difference often comes down to the layers under the panels, the roof deck style, and what’s happening in your attic.

This guide breaks down what causes metal roof rain noise , what counts as normal, what’s a red flag, and the safest ways to quiet things down without creating moisture problems.

Why some metal roofs get loud in heavy Florida rain

Cross-section showing how vibration from rain can travel through the roof assembly, and where insulation and membranes help (created with AI).

Cross-section showing how vibration from rain can travel through the roof assembly, and where insulation and membranes help (created with AI).

Rain noise is mostly impact noise , meaning raindrops physically hit the panel and create vibration. That vibration can pass into the roof deck and framing, then into the air inside the attic, and finally into your rooms as airborne sound. A metal roof isn’t automatically loud, but it can act like a “speaker cone” if the assembly lets panels flex and ring.

Here’s what usually separates normal rain sound from the “too loud” kind:

- Deck type (solid decking vs purlins): A solid plywood/OSB deck supports the panel and reduces the drum effect. Metal over open purlins (common on barns, some porch roofs, and some retrofits) leaves an air cavity that can amplify sound.

- Attachment method (clip-fastened vs exposed fastener): Clip-fastened standing seam tends to control vibration better and allows thermal movement without stressing fasteners. Exposed-fastener panels can get noisier if fasteners are overdriven, underdriven, backed out, or if panels “work” under wind load.

- Underlayment choice: A thin synthetic underlayment helps with water protection but doesn’t damp vibration much. A compatible self-adhered membrane (and in some cases, a dedicated sound-damping layer) can noticeably cut the sharp “ping” sounds.

- Attic geometry: A tall attic can buffer sound, but it can also echo if it’s empty and leaky. A low attic or a cathedral ceiling (little to no attic space) often sounds louder because there’s less separation from the roof.

If you’re also planning for wind-driven rain and hurricane conditions, the roof’s full assembly matters. This overview on hurricane-ready metal roof components in Central Florida helps connect the dots between layers, fastening, and performance.

Myth vs fact: metal roofs and rain noise

| Myth | Fact |

|---|---|

| “Metal roofs are always loud in rain.” | With solid decking, good underlayment, and a well-insulated ceiling, many homes sound similar to shingles. |

| “More attic insulation fixes it every time.” | Air sealing first is often the bigger win, insulation alone can leave sound leaks wide open. |

| “Any peel-and-stick will help.” | The membrane must be roof-system compatible and installed correctly to avoid adhesion and moisture issues. |

The quieting tools that work: damping, deck support, and attic absorption

Side-by-side comparison of assemblies that tend to be louder versus quieter (created with AI).

Side-by-side comparison of assemblies that tend to be louder versus quieter (created with AI).

Noise control is easier to understand if you think of three jobs: support the panel , dampen vibration , and absorb sound before it reaches the room . That’s why “just add insulation” sometimes disappoints.

1) Damping layers under the panel

A self-adhered membrane can add mass and “stick” the system together so it doesn’t ring as easily. Some assemblies also use specialty sound-damping products, but the key is compatibility with metal roofing, local code requirements, and manufacturer specs.

You also want the right underlayment for Florida conditions. Poorly chosen layers can trap moisture, especially if you create a vapor sandwich (a low-perm layer above and another low-perm layer below, with damp air stuck between).

2) Solid decking reduces the drum effect

If you’re building or re-roofing, metal over solid decking is one of the biggest factors in keeping rain sound at a reasonable level. Open purlins can be fine structurally, but they’re a common reason people describe the sound as “tin can loud.”

3) Attic insulation helps, but only if the ceiling plane is tight

Insulation works as sound absorption , and it also helps reduce the “pressure” of sound waves in the attic. But sound slips through holes the same places air does. Recessed lights, attic hatches, duct chases, and top plates can leak a surprising amount of sound.

A quick note on ratings: STC is used for airborne sound through walls/ceilings, while impact noise is a different beast. With rain, you’re fighting vibration first, then airborne sound second, so damping and tight assemblies matter.

Rough costs and what to expect (very general)

| Upgrade | Typical cost range | Expected noise change |

|---|---|---|

| Air sealing attic penetrations | Low to Medium | Noticeable in many homes |

| Add blown insulation over ceiling | Medium | Moderate improvement |

| Upgrade underlayment to self-adhered membrane (during reroof) | Medium to High | Moderate to strong improvement |

| Rebuild to solid decking (if currently on purlins) | High | Strong improvement |

New install checklist (best time to get it quiet)

- Choose a solid deck when possible (plywood/OSB), especially over living space.

- Confirm underlayment and membrane compatibility with the panel system and local requirements.

- For standing seam, consider clip-fastened profiles for controlled movement and reduced stress noise.

- Specify proper fastener patterns and avoid overdriving, vibration often starts at bad fastening.

- Plan attic ventilation details (or commit to a conditioned attic plan), don’t guess.

- Before closing ceilings, air seal the ceiling plane (top plates, chases, penetrations).

If you’re comparing panel types for a home, Florida standing seam metal roofing options are often selected for clean looks and clip-based attachment, which can help avoid some common vibration issues when installed correctly.

Quieting a metal roof from inside the attic (without creating moisture problems)

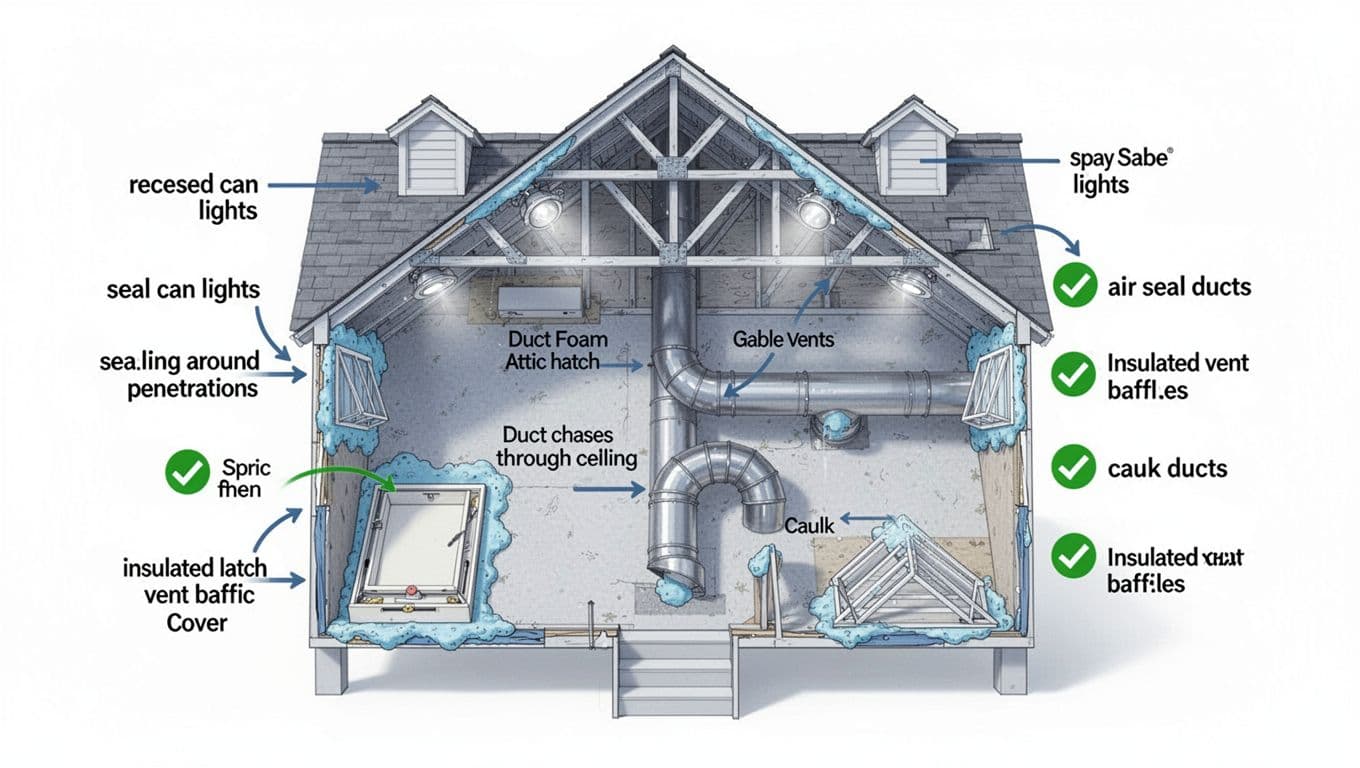

Common attic sound leaks and practical sealing targets that often reduce perceived rain noise (created with AI).

Common attic sound leaks and practical sealing targets that often reduce perceived rain noise (created with AI).

If your roof is already on, the attic is usually the safest place to work, but order matters. Air sealing comes first , then insulation. If you bury leaks under insulation, they still leak sound and air, and they’re harder to find later.

Retrofit checklist (attic-side, building-science safe)

- Seal big bypasses first: duct chases, plumbing stacks, bath fan housings, and open soffits.

- Tighten the attic hatch: weatherstrip it and add an insulated cover box.

- If you have recessed lights, use IC-rated airtight fixtures or approved covers, then seal.

- Seal top plates and wiring holes with caulk or foam rated for the application.

- Add or top off insulation to an appropriate R-value for your home and budget (many Florida homes aim for R-38 or higher at the ceiling).

- Keep ventilation pathways clear with baffles, don’t block soffit intake.

Ventilated attic vs conditioned attic (why it matters for noise)

Most Florida homes use a vented attic , where soffit and ridge (or gable) vents move hot, moist air out. In that setup, you generally want insulation on the attic floor and a tight ceiling plane.

A conditioned attic (spray foam at the roof deck, ducts inside conditioned space) can also reduce noise because the roofline becomes part of the thermal and air boundary. It’s a bigger design choice, and it must be done as a system to avoid moisture issues.

When to call a roofer or insulation pro

- You have cathedral ceilings or very little attic access.

- The noise is paired with panel popping, movement, or rattling in wind.

- You suspect missing underlayment, poor fastening, or a deck problem.

- You see moisture signs (moldy sheathing, rusty fasteners, wet insulation).

- You want to change ventilation strategy or move to a conditioned attic.

For a real-world look at what builders try on steel and metal roofs, this sound reduction discussion in a steel-building forum thread highlights how often the best results come from tightening assemblies, not just adding fluffy insulation.

Rain on a metal roof will always have a sound, that’s part of the material’s character. The goal is getting it back to normal , where you hear the storm without feeling like you’re inside it. Start with the assembly basics, seal the ceiling plane, then add insulation in a way that keeps your attic dry and your home comfortable. If you’re hearing sharp pinging, rattles, or sudden changes in loudness, treat that as a signal to check fastening and layers, not just a reason to add more insulation.