The Anatomy of a Hurricane-Ready Metal Roof: Essential Components for Central Florida

The Anatomy of a Hurricane-Ready Metal Roof: Essential Components for Central Florida

Understanding Florida's Unique Challenges for Metal Roofing

Central Florida is no stranger to severe weather, with hurricanes, high winds, and torrential rain being regular occurrences. These conditions pose significant challenges to roofing systems, as they must withstand wind speeds that can exceed 100 miles per hour and heavy rainfall that can lead to leaks and structural damage. The combination of these elements makes it essential for homeowners to choose roofing materials and designs specifically engineered to endure such extreme weather. Without proper preparation, roofs in this region are at risk of failure, leading to costly repairs or even total replacement.

To combat these challenges, metal roofs are increasingly becoming the go-to choice for Central Florida homeowners. Unlike traditional shingles, metal roofs offer superior durability and resistance to wind uplift, making them ideal for hurricane-prone areas. However, not all metal roofs are created equal. Specific design and structural considerations, such as panel profiles, fastening systems, and underlayment choices , play a critical role in ensuring a roof can withstand the unique demands of Florida’s climate. By addressing these factors, homeowners can significantly enhance their property's resilience against nature's fury.

Florida Building Codes and Compliance for Metal Roofs

The Florida Building Code (FBC) sets strict requirements for roofing systems in hurricane-prone areas, ensuring they can withstand the region's harsh weather conditions. One of the most critical aspects of the code is the wind resistance rating, which mandates that roofs meet specific standards based on their location within the state. Coastal zones, for example, often require higher wind resistance ratings compared to inland areas due to their increased exposure to storm surges and stronger winds. Additionally, the FBC requires product approvals , meaning only materials tested and certified for use in high-wind zones can be installed.

Adhering to these codes is not just about legal compliance; it’s about safety and protection. Using non-compliant products or cutting corners during installation can compromise a roof’s ability to withstand a hurricane, putting both property and lives at risk. Furthermore, insurance companies often require proof of code compliance to provide coverage, making it a practical necessity for homeowners. By strictly following the FBC guidelines, homeowners can ensure their metal roofs are built to last and capable of withstanding the worst that Florida’s weather can throw at them.

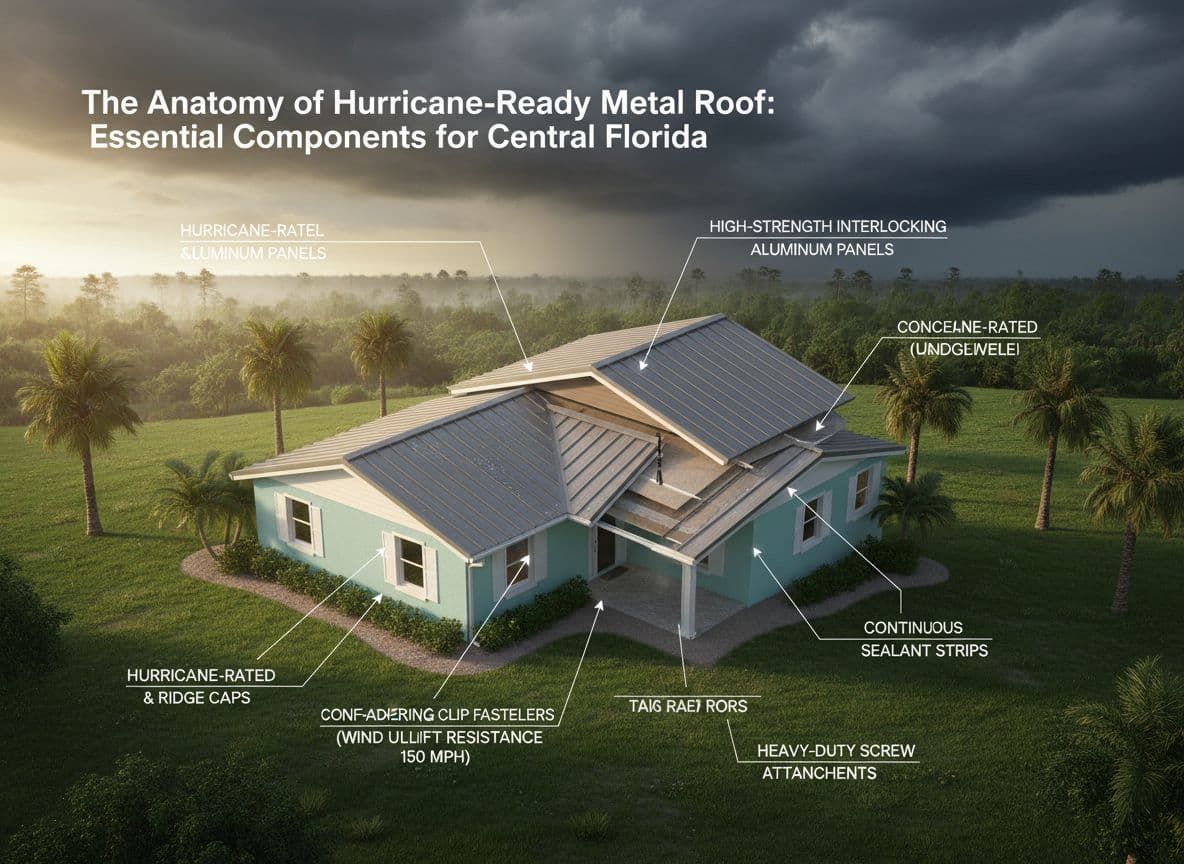

Essential Structural Components of a Hurricane-Resistant Metal Roof

A hurricane-resistant metal roof relies on several key structural components working together to ensure strength and stability. At the foundation of this system is the roof decking, which serves as the base layer supporting the entire structure. The decking must be securely attached to the trusses, which are designed to distribute weight evenly and resist uplift forces during high winds. In hurricane-prone areas like Central Florida, the FBC specifies minimum thickness requirements for decking materials to prevent warping or failure under stress.

Fasteners and bracing are equally critical to a roof’s performance during a storm. High-quality fasteners with corrosion-resistant coatings are essential to prevent loosening over time, while proper bracing techniques help reinforce the roof against lateral movement. These elements work in tandem to create a cohesive system capable of withstanding hurricane-force winds. When installed correctly, these structural components form the backbone of a durable and reliable roofing system.

Finally, attention to detail during installation is crucial to achieving optimal performance. Even the strongest materials can fail if not properly secured or aligned. For instance, improper spacing of fasteners or inadequate bracing can create weak points that compromise the roof’s integrity. By adhering to code standards and manufacturer guidelines, installers can ensure that every component functions as intended, providing homeowners with peace of mind during hurricane season.

Material Selection: Metals, Panel Profiles, and Finishes

Choosing the right materials is a critical step in building a hurricane-ready metal roof. Aluminum and steel are two of the most popular options , each offering unique benefits for Central Florida’s climate. Aluminum is lightweight, corrosion-resistant, and performs exceptionally well in coastal areas where salt air can accelerate rusting. Steel, on the other hand, is incredibly strong and can be coated to enhance its durability and resistance to weathering. Both materials are excellent choices, but the decision often comes down to budget, aesthetic preferences, and specific environmental factors.

In addition to material selection, the panel profile plays a significant role in a roof’s performance. Panels with standing seams or interlocking designs are preferred for their superior wind uplift resistance and ability to facilitate proper water drainage. Protective finishes, such as powder coatings or paint systems, further enhance the roof’s longevity by shielding it from UV rays, moisture, and debris. Together, these elements ensure that the roof not only withstands hurricanes but also maintains its appearance and functionality over time.

Underlayment and Moisture Barriers: The First Line of Defense

Underlayment serves as the first line of defense against wind-driven rain and moisture intrusion, making it a vital component of any hurricane-ready metal roof. Modern underlayments, including sealed deck systems and peel-and-stick barriers, are designed to provide an additional layer of protection between the roof panels and the decking. These materials are engineered to adhere tightly to the surface, preventing water from seeping through even during the heaviest storms. Recent updates to building codes have emphasized the importance of high-quality underlayments, particularly in hurricane-prone regions like Central Florida.

Proper installation of underlayment is just as important as the material itself. Best practices include ensuring a smooth, wrinkle-free application and overlapping seams to create a continuous barrier. Neglecting these steps can lead to vulnerabilities that compromise the roof’s ability to keep water out. By prioritizing the quality and installation of underlayment, homeowners can significantly reduce the risk of leaks and water damage during severe weather events.

Attachment Systems: Fasteners, Clips, and Seams

The attachment system is a critical factor in determining a metal roof’s wind resistance and water tightness. The Florida Building Code mandates the use of specific fasteners, sealing washers, and clips designed to withstand hurricane-force winds. Concealed fasteners and mechanically seamed panels are often preferred over exposed fasteners because they minimize the risk of water infiltration and provide a sleek, uniform appearance. These systems also reduce the likelihood of fastener loosening over time, which can occur with prolonged exposure to high winds and vibrations.

Properly securing the panels to the roof structure is equally important. Clips and fasteners must be spaced and aligned according to manufacturer specifications to ensure maximum strength and stability. Failure to follow these guidelines can result in weak points that compromise the roof’s performance during a storm. By using code-compliant attachment methods and materials, homeowners can rest assured that their roof is built to withstand the harshest conditions Central Florida has to offer.

Edge and Eave Protection Measures

The edges and eaves of a metal roof are among the most vulnerable areas during a hurricane, as they are often the first to experience wind uplift and water intrusion. Secure edge details, such as drip edges and starter strips, play a crucial role in reinforcing these areas and preventing damage. Drip edges direct water away from the roof and fascia, reducing the risk of rot and structural compromise, while starter strips provide a stable base for the first row of panels. Proper installation of these components is essential to ensure they function effectively during a storm.

Common failure points at the edges and eaves include improperly secured fasteners and inadequate flashing. To address these risks, the Florida Building Code requires specific reinforcement methods, such as using heavier gauge materials and adding additional bracing. By paying close attention to these details, homeowners can significantly enhance their roof’s ability to withstand high winds and heavy rain, protecting their property from costly damage.

Proper Installation Practices for Hurricane-Ready Roofs

Even the highest-quality materials and components can fail if not installed correctly, making proper installation practices a cornerstone of a hurricane-ready metal roof. Key steps include inspecting the roof deck for any defects or weaknesses before installation begins. Ensuring the deck is clean, dry, and structurally sound is essential to creating a stable foundation for the new roof. Additionally, precise measurement and cutting of panels are critical to achieving a snug fit that minimizes gaps and potential weak points.

Professional installation is highly recommended for hurricane-rated metal roofs, as experienced contractors are familiar with the latest building codes and best practices. Following manufacturer guidelines is equally important, as deviations can void warranties and compromise the roof’s performance. By entrusting the project to skilled professionals, homeowners can ensure their roof is built to last and capable of withstanding the worst that Florida’s weather can throw at it.

Ventilation and Insulation Considerations

Proper ventilation is essential for maintaining the longevity and performance of a metal roof in Central Florida’s humid climate. Without adequate airflow, moisture can accumulate in the attic, leading to mold growth, wood rot, and reduced energy efficiency. Ridge vents, soffit vents, and other ventilation systems help regulate temperature and humidity levels, ensuring the roof remains dry and structurally sound. These systems work in tandem with insulation to create a balanced environment that protects the home from the elements.

When selecting insulation for a hurricane-rated metal roof, homeowners should prioritize options that are compatible with the roof’s design and local climate. Spray foam insulation, for example, provides excellent thermal performance and helps prevent condensation by creating an airtight seal. By combining proper ventilation with high-quality insulation, homeowners can maximize energy savings and ensure their roof performs optimally year-round.

Regular Inspections and Maintenance for Longevity

Regular inspections and maintenance are key to extending the lifespan of a hurricane-ready metal roof. Homeowners should schedule semi-annual checkups to identify and address minor issues before they escalate into major problems. After a storm, it’s especially important to inspect the roof for signs of damage, such as loose fasteners, dented panels, or compromised seals. Prompt repairs can prevent water intrusion and structural compromise, ensuring the roof remains in top condition.

Maintenance tasks may include cleaning debris from gutters and drains, tightening loose fasteners, and resealing any worn areas. While some tasks can be performed by homeowners, others may require professional assistance to ensure safety and accuracy. By staying proactive and addressing potential issues early, homeowners can enjoy peace of mind knowing their roof is ready to face whatever Mother Nature has in store.

Cost vs. Benefit: Investing in Hurricane-Resistant Metal Roofs

While the initial cost of a hurricane-ready metal roof may be higher than traditional shingle roofs, the long-term benefits often outweigh the investment. Metal roofs are more durable, requiring fewer repairs and replacements over their lifespan, which can exceed 50 years with proper care. Additionally, many insurance companies offer premium discounts for homes with hurricane-resistant roofs , helping offset the upfront expense. Energy savings from improved insulation and ventilation further contribute to the overall value of the investment.

Beyond financial considerations, metal roofs provide unparalleled peace of mind for Central Florida homeowners. Their ability to withstand high winds, heavy rain, and debris impact ensures family safety and property protection during hurricanes. By choosing a metal roof, homeowners not only enhance their home’s resilience but also increase its market value, making it a smart and responsible decision for the future.

Common Mistakes to Avoid in Central Florida Metal Roofing Projects

One of the most common mistakes in metal roofing projects is using non-approved products that do not meet Florida Building Code requirements. These materials may appear cost-effective initially but can lead to costly repairs or even complete roof failure during a hurricane. Similarly, poor flashing details around chimneys, skylights, and vents can create weak points that allow water intrusion. Homeowners should always verify that all materials and components are code-compliant and installed according to manufacturer guidelines.

Another frequent error is improper attachment methods, such as using incorrect fasteners or failing to secure panels adequately. These oversights can compromise the roof’s wind resistance and water tightness, leaving it vulnerable to storm damage. Working with experienced professionals who understand the nuances of hurricane-ready roofing is the best way to avoid these pitfalls and ensure a successful project.

Frequently Asked Questions

How does the Florida Building Code affect the choice of metal roofing products?

The Florida Building Code requires that all metal roofing products used in hurricane-prone areas meet specific wind resistance and impact ratings. This ensures that only materials tested and proven to withstand severe weather are installed, providing homeowners with added protection and peace of mind. Using non-approved products can result in failed inspections, denied insurance claims, and increased vulnerability during storms.

Are all metal roofs hurricane resistant?

No, not all metal roofs are hurricane resistant. Only systems that are code-approved and properly installed with specific wind and impact ratings qualify as hurricane resistant. Factors such as material quality, panel profile, and attachment methods all contribute to a roof’s ability to withstand extreme weather conditions.

What is the best type of metal for Central Florida's climate?

Aluminum and coated steel are both excellent choices for Central Florida’s climate. Aluminum offers superior corrosion resistance, making it ideal for coastal areas with salt air, while coated steel provides exceptional strength and durability. The choice ultimately depends on budget, aesthetic preferences, and specific environmental factors.

How often should a hurricane-ready metal roof be inspected?

A hurricane-ready metal roof should be inspected at least twice a year and after every major storm. Priority areas include fasteners, seams, flashings, and edges, as these are common points of failure during high winds and heavy rain. Regular inspections help identify and address minor issues before they escalate.

Can an existing roof structure support a hurricane-ready metal roof?

An existing roof structure may support a hurricane-ready metal roof, but a thorough assessment is required to determine its condition and load-bearing capacity. In some cases, roof deck or truss reinforcement may be necessary to safely install the new system. Consulting a structural engineer or licensed contractor is the best way to ensure compatibility and safety.

Conclusion: Ensuring Safety and Value with a Hurricane-Ready Metal Roof

A hurricane-ready metal roof is more than just a protective covering; it’s an investment in safety, longevity, and property value. By combining code compliance, high-quality materials, and expert installation, homeowners in Central Florida can create a resilient roofing system capable of withstanding the region’s challenging weather. From structural components like decking and trusses to critical details like underlayment and fasteners, every element plays a vital role in ensuring the roof’s performance during a storm.

Taking proactive steps to meet local building regulations and protect your home is essential for peace of mind. If you’re considering a new metal roof or evaluating your current system, consult experienced, licensed professionals who specialize in hurricane-ready solutions. They can guide you through the process, ensuring your roof is built to last and ready to face whatever nature throws its way.