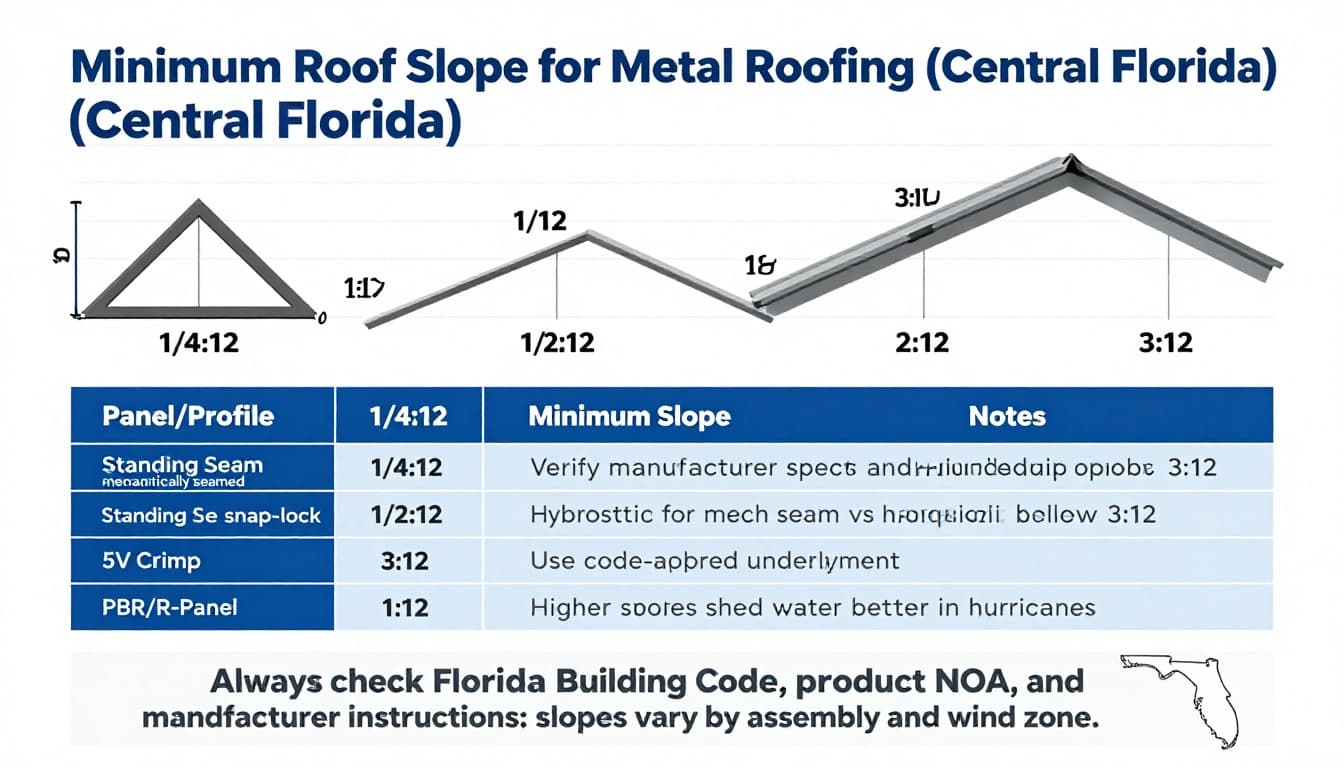

Minimum roof slope for metal roofing in Central Florida, standing seam vs. 5V Crimp vs. PBR (simple slope chart)

If you’re planning a metal roof in Central Florida, the slope matters more than most people think. A roof that looks “almost flat” can handle sunshine all day, then struggle the first time wind-driven rain gets pushed uphill during a summer storm.

The tricky part is that there isn’t one single minimum for every panel. The metal roof slope you can use depends on the panel profile, how the seams lock, whether laps are sealed, and the exact Florida Product Approval or manufacturer instructions for that assembly.

Below is a simple chart you can reference fast, followed by the “why” behind it, and what to do when your roof is on the low-slope side.

Simple slope chart (typical minimums, verify your exact system)

Infographic showing common minimum slopes by panel type, created with AI.

Infographic showing common minimum slopes by panel type, created with AI.

Here are typical minimum roof slopes used across Florida projects, including Central Florida. Treat these as starting points, not final approval. Always confirm the exact panel’s installation manual and its Florida Product Approval, because details like clip type, seam height, underlayment, and sealant locations can change the allowed slope.

| Panel / Profile | Typical minimum slope (Central FL) | What that means in plain English |

|---|---|---|

| Standing seam (mechanically seamed, “hydrostatic”) | 1/4:12 | Built for low slope, seams are mechanically locked to resist water backup. |

| Standing seam (snap-lock, often “hydrokinetic”) | 1/2:12 to 3:12 (varies a lot) | Snap systems shed water well, but many aren’t intended for ponding or slow drainage. |

| 5V Crimp (exposed fastener) | 3:12 | Best on steeper roofs, relies on gravity and fastener washers. |

| PBR / R-panel (exposed fastener) | 3:12 | Common for commercial and barns, but still wants steeper slope unless a specific sealed-lap assembly is approved. |

A note that surprises people: some exposed-fastener panels can be approved for lower slopes only when the sidelaps and end-laps are sealed as part of a tested assembly. That’s not “optional caulk,” it’s a defined method that must match the approval.

Why slope matters so much in Central Florida storms

Low-slope standing seam shedding water during heavy rain, created with AI.

Low-slope standing seam shedding water during heavy rain, created with AI.

Roof slope is like a slide at a pool. The steeper it is, the faster water gets off the surface. When the pitch is low, water moves slowly, and that gives wind time to push it into seams, laps, and fastener points.

In Central Florida, you don’t just get “rain.” You get rain that comes sideways during thunderstorms, tropical systems, and hurricanes. That wind-driven rain is the real test for a low-slope roof, because it can:

- Stack water at seams and end-laps , especially on long runs.

- Find small gaps around penetrations (pipes, skylights, curbs) where flashing wasn’t designed for low slope.

- Expose weak details like poorly aligned closures, stretched fastener spacing, or overdriven screws.

This is why it’s smart to be conservative with metal roof slope in 2026. Even when code minimums allow a low pitch, real-world performance depends on the whole assembly, not just the panel shape. Florida Building Code requirements, local permitting practices, and product approvals are there to prevent obvious failures, but good detailing is what keeps a roof dry after years of sun, heat, and storm cycles.

Standing seam vs. 5V Crimp vs. PBR: what changes at low slope

Not all metal roofs handle slow drainage the same way. The key difference is whether the system is designed to resist water that lingers or backs up.

Mechanically seamed standing seam (hydrostatic)

This is the go-to for very low slopes because the seams are mechanically folded together. Done correctly, a hydrostatic standing seam can manage water that moves slowly, and it’s also easier to detail without relying on exposed fasteners across the field of the panel.

For Central Florida, 1/4:12 is a common minimum for mechanically seamed systems, but verify the exact product approval and installation manual. Small choices, like seam type and seam sealant requirements, can change what’s allowed.

Snap-lock standing seam (often hydrokinetic)

Snap-lock systems can be great on many homes, but the slope requirements vary widely. Many snap-lock panels are intended to shed water (hydrokinetic), not hold back water that stacks up. On a low slope, that difference matters.

If your roof is close to flat, don’t assume “standing seam” automatically means “1/4:12.” Ask whether the system is rated for your specific slope and exposure.

5V Crimp (exposed fastener)

5V Crimp is a classic Florida look, especially on coastal-style homes. But it usually needs a steeper pitch because the system depends on gravity and on hundreds (or thousands) of fastener washer seals staying tight over time.

A typical minimum is 3:12 . Below that, you’re more likely to see slow leaks at end-laps, around fasteners, or where panels aren’t perfectly flat.

PBR (R-panel, exposed fastener)

PBR is popular for light commercial buildings, shops, and agricultural roofs. It’s strong, installs fast, and handles wind well when it’s part of a tested assembly. But for water, it’s still an exposed-fastener roof at heart. 3:12 is the common minimum unless a specific sealed-lap assembly is approved for less.

Low-slope metal roof recommendations that reduce leak risk

If your roof design is pushing the lower edge of what’s allowed, the details matter more than the panel choice. These are practical moves that help low-slope metal roofs perform better in Central Florida’s wet, windy seasons:

- Choose the right system for the pitch : If you’re near 1/4:12 to 1/2:12, mechanically seamed standing seam is usually the safer direction than exposed-fastener panels.

- Be strict about sealant strategy : Use sealants where the manufacturer requires them (often at seams, end-laps, and transitions). On low slopes, skipping a bead because “it’s probably fine” is how call-backs happen.

- Upgrade underlayment intentionally : Low slope often benefits from higher-performing self-adhered membranes in critical areas (eaves, valleys, transitions, penetrations), as allowed by code and the manufacturer. The underlayment is the backup plan, treat it like one.

- Avoid end-laps when you can : Long, continuous panels reduce the number of horizontal joints that can trap water. When end-laps are unavoidable, follow the specified lap length, butyl placement, and fastener pattern exactly.

- Add slope with tapered insulation or crickets : If you’re fighting ponding near a wall, curb, or rooftop unit, adding slope is sometimes the cleanest fix. Think of it as guiding water off the roof instead of arguing with it.

- Detail penetrations like they’re on a flatter roof than they look : Pipe boots, curbs, and flashings need to be compatible with low slope and metal movement. Expansion and contraction are real in Florida heat.

One more reality check: a low-slope roof can be “to code” and still be unforgiving if installation quality slips. Layout, fastener placement, panel alignment, and trim details all show up during the first big storm.

Final check before you commit to a slope

Before ordering panels or signing an install contract, confirm three things for your exact roof: the Florida Building Code requirements for the roof covering type, the panel’s Florida Product Approval or NOA (as applicable), and the manufacturer’s installation manual for the exact assembly you’re using.

This guide shares common, real-world minimums, not a guarantee. Your safest move is to match the panel to the metal roof slope you actually have, then detail it like you expect a hurricane season, because in Central Florida, you should.