Florida Product Approval and Miami-Dade NOA for Metal Roofing, how to pick compliant panels and trim

A metal roof can look simple from the curb, panels, screws, and trim that all match. In Florida, it’s more like a tested recipe. Swap one ingredient and the whole assembly may no longer be approved.

That’s why permit reviewers and inspectors keep asking for Florida product approval and, in the High Velocity Hurricane Zone (HVHZ), a Miami-Dade NOA. They’re not looking for paperwork to be difficult. They’re confirming the exact roof system on your plans is the same system that was tested.

This guide breaks down how to choose compliant metal panels and trim, and how to verify the approvals before you order.

Florida Product Approval vs Miami-Dade NOA (and why both can matter)

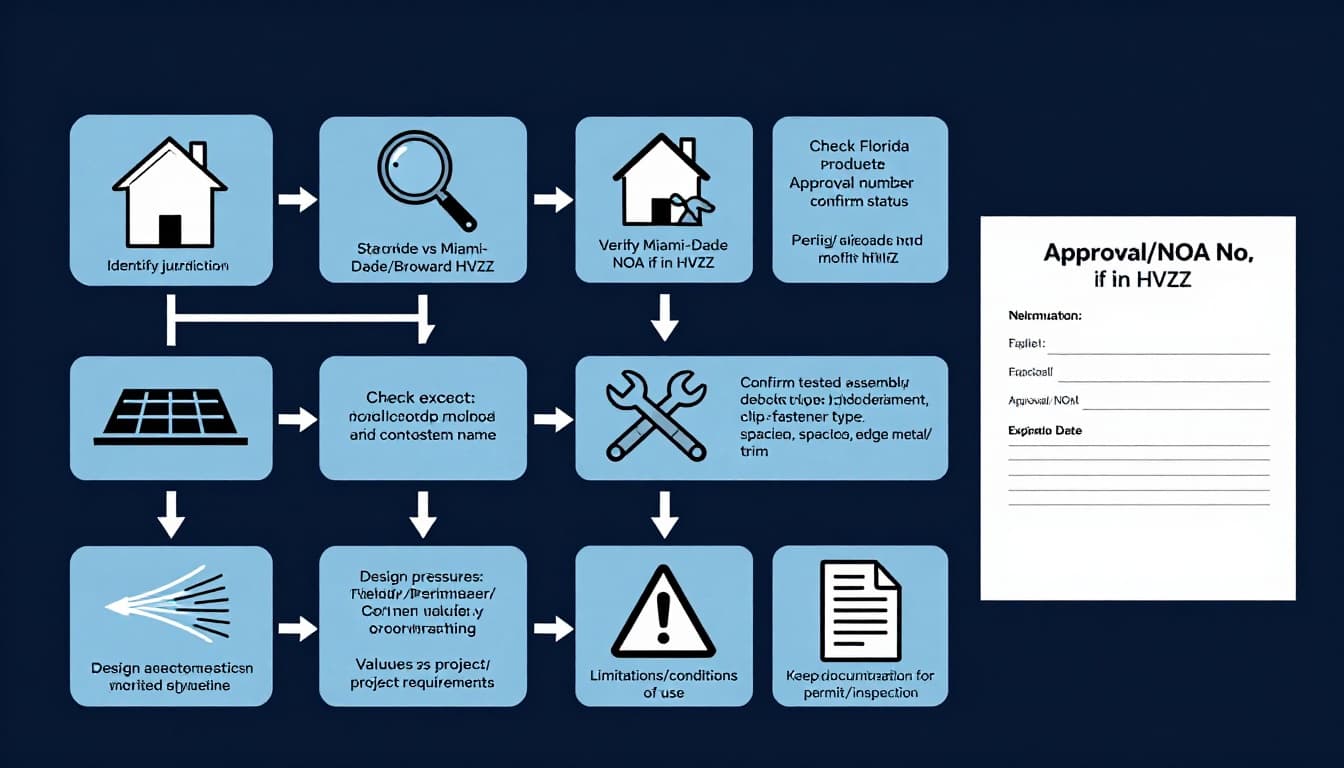

Flowchart showing a practical path to confirm approvals, assembly details, and design pressures, created with AI.

Flowchart showing a practical path to confirm approvals, assembly details, and design pressures, created with AI.

Florida Product Approval (often shown as an “FL#” or Florida Product Approval number) is the statewide acceptance path used for many building products, including metal roofing systems. For permits, you usually need to show the current approval and the installed assembly must match the approved assembly.

Miami-Dade NOA (Notice of Acceptance) is issued through Miami-Dade County’s Product Control program. If the project is in HVHZ (Miami-Dade and Broward) , the NOA is often required. Many jurisdictions outside HVHZ also accept or request NOAs because they’re familiar and very detailed, but the local building department sets that rule.

Here’s the part that trips people up: approvals are assembly-specific , not “this metal panel is approved in Florida.” The same panel profile can have different approvals depending on:

- Deck type (plywood, OSB, purlins, steel deck, lightweight insulating concrete, etc.)

- Underlayment type and attachment

- Fastener type and spacing, and clip details for standing seam

- Edge metal and trim attachment

- Tested design pressures

To look up what’s current (not a screenshot, not a PDF someone emailed three years ago), use the official databases:

- Florida: Florida Product Approval search

- Miami-Dade: Miami-Dade Product Control search

As of January 2026, most projects are still permitted under the Florida Building Code currently in effect in your area, but the larger point stays the same: use the approval that matches the code cycle and is not expired .

How to read approval documents like an inspector does

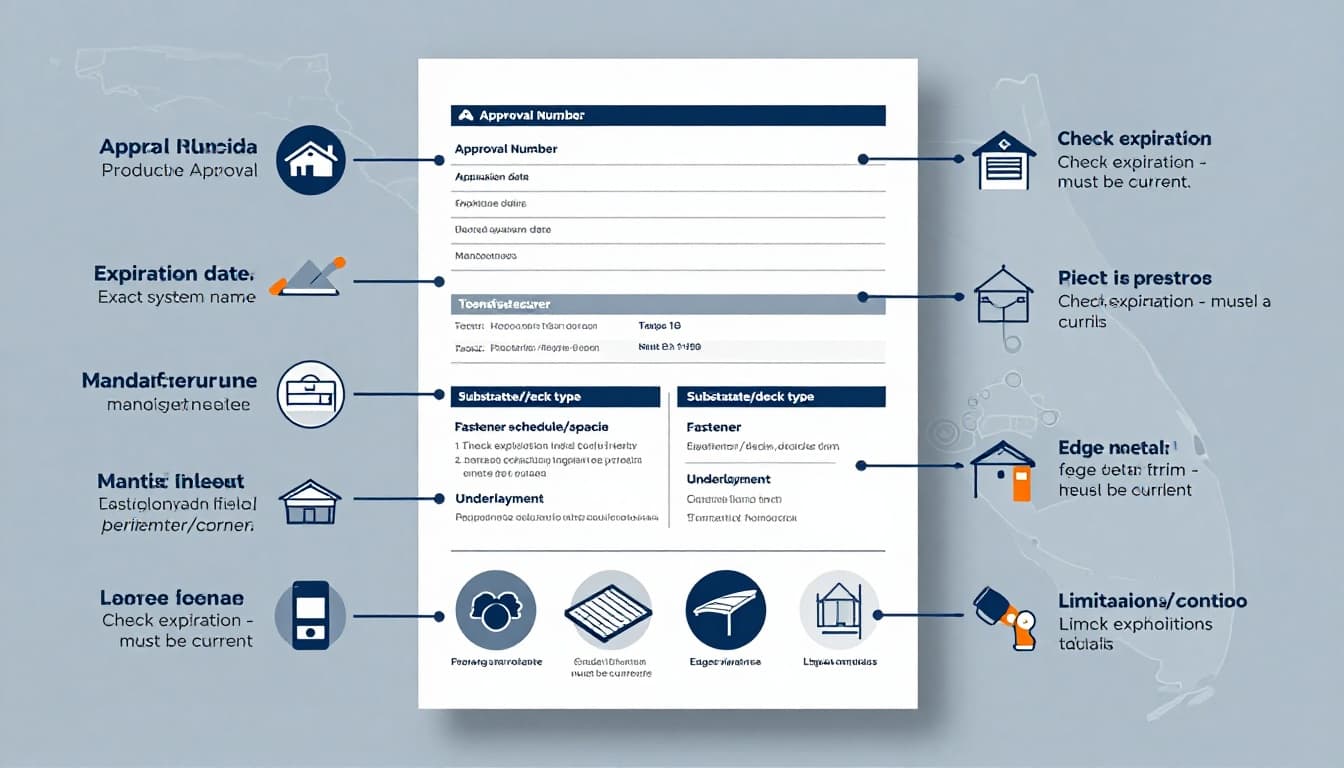

Key fields to cross-check on an approval package before submittals, created with AI.

Key fields to cross-check on an approval package before submittals, created with AI.

Approval packages can feel like a stack of technical pages, but inspectors tend to check the same few items again and again. If you cross-check these early, you avoid last-minute re-orders and re-submittals.

Start with identity and status:

- Exact product or system name : Match the panel profile name and configuration exactly (standing seam clip system vs nail strip, exposed-fastener vs concealed, etc.).

- Manufacturer : Verify the approval is for the manufacturer supplying the panels, not a similar profile from another source.

- Current status and expiration date : If it’s expired or superseded, it’s a permit problem.

Then match the approved assembly details to your roof:

- Substrate or deck : A panel approved over plywood may not be approved over purlins, and vice versa. Don’t assume.

- Underlayment : The approval often calls out specific types, layers, and attachment methods. HVHZ rules are commonly stricter.

- Fastener schedule : This is where approvals get very specific, screw type, diameter, corrosion protection, and spacing. Edge zones often require tighter spacing.

- Trim and edge metal : Look for how drip edge, rake, ridge, hip, valley, and wall flashings are attached. Some approvals reference tested edge metal details or limitations on what’s allowed.

Finally, check pressures and limits:

- Design pressures : Many systems list values for field, perimeter, and corner zones. Compare those values to the project’s required pressures from the engineer or code calculations. A roof can “pass” in the field and still fail at corners.

- Limitations and conditions of use : These are the fine print items that decide whether the approval applies to your job, like minimum deck thickness, max span over purlins, or where sealant is required.

- For Miami-Dade, pay attention to Maximum Design Pressure (MDP) and any installation notes that say “no deviations.”

A practical workflow to pick compliant panels and trim (before you order)

The easiest way to stay compliant is to decide the roof assembly first, then pick the panel and trim that match it, not the other way around. Think of it like buying tires. The tread can be great, but if the load rating doesn’t match the vehicle, it’s the wrong tire.

If you’re comparing options, start with approved assemblies and documentation. Many suppliers organize approvals by profile and deck condition, like these Florida product approval listings for metal roofing.

Use this short checklist as your pre-order verification:

- Jurisdiction : Confirm if the job is in HVHZ (Miami-Dade or Broward) and if the building department requires an NOA in addition to Florida Product Approval.

- Panel profile and gauge : Match the exact profile, metal thickness, and finish described in the approval.

- Deck and attachment : Verify the approval is for your substrate (plywood, OSB, purlins, steel deck, etc.) and the stated attachment method.

- Underlayment : Confirm the required underlayment type, number of plies, and how it’s fastened.

- Fasteners or clips : Match the screw or clip type and spacing, including tighter patterns in perimeter and corner zones.

- Trim and edge metal : Confirm approved details for drip edge and rake, plus ridge, hip, valley, and wall flashings as applicable.

- Pressures : Compare listed field, perimeter, and corner pressures to the project’s required pressures.

- Documentation : Save the approval cover page, the installation pages referenced by the approval, and the selected assembly page for the permit set.

Choosing panels is only half the job. Trim is where a lot of “almost compliant” installs fall apart, especially at eaves and rakes where wind starts peeling. If you’re selecting a panel profile for higher wind areas, review a system with HVHZ options, such as Florida-approved PBR panels , and make sure the edge metal and fastener pattern shown on the approval matches what will be installed.

Avoid these common compliance mistakes

- Using the right panel with the wrong deck : The approval is tied to the tested substrate.

- Mixing fasteners : “Equivalent” screws are not equivalent if the approval lists a specific type and diameter.

- Ignoring corner zones : Corners often control the design pressure check.

- Assuming trim is generic : Edge metal attachment details matter, and some assemblies are picky.

- Submitting old PDFs : Always re-check the databases right before permit submittal.

Conclusion

Metal roofing in Florida rewards people who match the tested system, not just the look. When you verify Florida product approval , confirm Miami-Dade NOA in HVHZ, and cross-check the assembly details, you cut down on permit delays and avoid expensive changes after delivery. Keep the approval pages with the job file so the inspector can see what you installed. The extra 20 minutes upfront is often the difference between a smooth final and a frustrating rework.

Share Our Metal Roofing News Articles

Related Posts