Metal Roof Retrofit Over Shingles in Central Florida, When It’s Allowed, When It’s a Bad Idea

A metal roof retrofit over shingles can feel like putting a new, tough shell over an older roof, faster, cleaner, and often cheaper than a full tear-off. In Central Florida, that sounds tempting, especially after storm season.

But an overlay is not a “cover it and forget it” project. Whether it’s allowed, and whether it’s smart, comes down to the roof you already have, the metal system you plan to install, and what your local building department (the AHJ) will approve.

This guide compares metal-over-shingles vs. tear-off in plain terms, with the code and wind realities Central Florida homeowners live with.

What code, wind loads, and approvals really control in Central Florida

Florida doesn’t treat roofing like a cosmetic upgrade. The roof is part of the home’s wind-resisting system, and your metal system has to match the approval paperwork and the installation instructions.

In most Central Florida areas, the Florida Building Code (FBC) points you toward a few non-negotiables:

- Local AHJ rules still decide the final yes or no. Even if a method is generally allowed, your county or city can require details like enhanced fastening, specific underlayments, or engineering.

- Manufacturer instructions are part of “code.” If the panel, underlayment, clip, or fastener schedule says one thing and the crew does another, inspectors can red-tag it, and warranties can get messy.

- Wind-uplift ratings matter as much as wind speed. Central Florida often lands in roughly the 130 to 150 mph design-wind conversation depending on exact location, exposure, and building height. The roof assembly must resist uplift, not just “handle wind.”

- Product approvals are a big deal. Florida Product Approval and, in many cases, Miami-Dade NOA based systems are how inspectors verify the roof assembly is tested and approved. If you change parts, you may change the assembly.

- The 25% rule can force upgrades. If more than 25% of the roof area is repaired or replaced in a 12-month period, the rest may need to be brought up to current code requirements.

That’s why the “metal over shingles” question is never only about panels. It’s about the whole tested, permitted assembly.

When a metal roof retrofit over shingles is allowed

Cross-section of a code-minded metal-over-shingles assembly with ventilation and proper flashing, created with AI.

Cross-section of a code-minded metal-over-shingles assembly with ventilation and proper flashing, created with AI.

An overlay can be a solid option when the existing roof is basically acting like a stable substrate, not a failing layer you’re trapping under metal. The most successful retrofits treat the metal roof as an independent, wind-rated system that transfers loads correctly into the structure.

Allowed when…

- One shingle layer is present (no second layer hiding below).

- The shingles are flat and well-bonded , with no widespread curling, buckling, or missing fields.

- The roof deck is solid and dry , with no soft spots, active leaks, or long-term staining from repeated wetting.

- The attachment method provides reliable fastener embedment (fasteners long enough to meet the required penetration into deck or framing, per the system approval).

- A code-accepted separation layer or underlayment is installed as required by the system approval, helping manage wind-driven rain and reduce abrasion between materials.

- Flashing details are rebuilt , not “worked around,” especially at eaves, rakes, valleys, sidewalls, and penetrations.

- Ventilation stays functional , either by maintaining soffit-to-ridge airflow or by meeting the requirements for an unvented attic approach when applicable.

- The exact panel system and assembly match Florida Product Approval or NOA documentation , including clip spacing, fastener patterns, and edge metal details.

A clean overlay can also reduce landfill waste and cut tear-off time, which matters when weather windows are tight.

When it’s a bad idea (even if someone says they can do it)

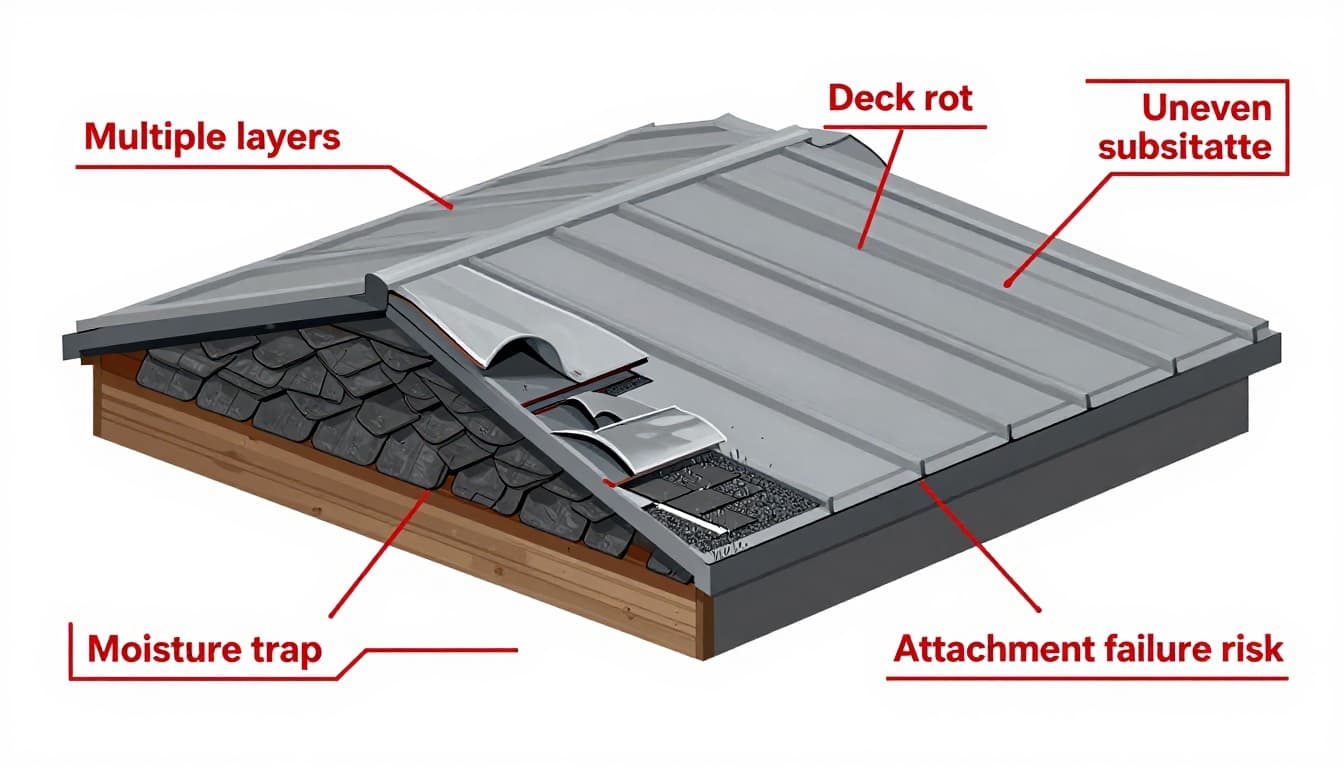

Common failure points that make overlays risky in Florida conditions, created with AI.

Common failure points that make overlays risky in Florida conditions, created with AI.

A metal roof can last decades, but it can’t “fix” a roof system that’s already failing underneath. In Central Florida, trapped moisture and weak attachment are the two big enemies, and both get worse when you bury problems.

Bad idea when…

- There are two layers of shingles , or you can’t confirm how many layers exist.

- The deck has rot, sagging, or delamination , or you feel bounce underfoot during a walkover.

- You have active leaks , chronic staining, or moldy attic smells that point to ongoing moisture.

- The shingle surface is wavy or curled , which can telegraph into the metal as oil-canning or visible distortion (especially on flatter-looking profiles).

- The plan relies on short fasteners that barely grab, or that miss solid wood and end up with weak holding power.

- Valleys and sidewalls have complex flashing history (patched tar, layered metal, mismatched materials). Overlaying often hides the clues you need to rebuild it correctly.

- Ventilation is already borderline , with blocked soffits, no ridge exhaust, or bath fans dumping into the attic.

- The retrofit assembly can’t be matched to an approved uplift-rated system , or the contractor is “mixing and matching” parts outside the approval.

If your roof is already telling you it’s tired, a tear-off usually isn’t a punishment. It’s access.

A contractor-style inspection checklist before choosing overlay vs. tear-off

This is the quick, practical list many crews run through before they commit to a metal-over-shingles scope. It also helps homeowners ask sharper questions.

- Confirm shingle layers at the drip edge and around penetrations. Verify it’s one layer.

- Walk the roof for flatness and note ridges, humps, and curled tabs.

- Probe the deck from the attic where possible (look for dark staining, mold, rusted nails, or sagging sheathing).

- Check ventilation paths : clear soffit intake, clear ridge exhaust, no blocked baffles.

- Measure roof slope and confirm it meets the metal system’s minimum slope and detailing needs.

- Identify high-risk leak zones : valleys, chimney or wall intersections, skylights, plumbing vents, and low transitions.

- Verify edge metal condition and plan for code-compliant drip edge and rake detailing.

- Select an approved assembly (Florida Product Approval or NOA as applicable) and match every component: panel, underlayment, clips, fasteners, closures, and sealants.

- Confirm fastener embedment requirements for your structure (deck thickness, truss spacing, and where the system expects to anchor).

- Document it for permits : photos, product approvals, and the installation plan the inspector will see.

If any of these checks raise doubts, a tear-off often becomes the safer, simpler path.

Cost, risk, and permitting: the real tradeoff in Central Florida

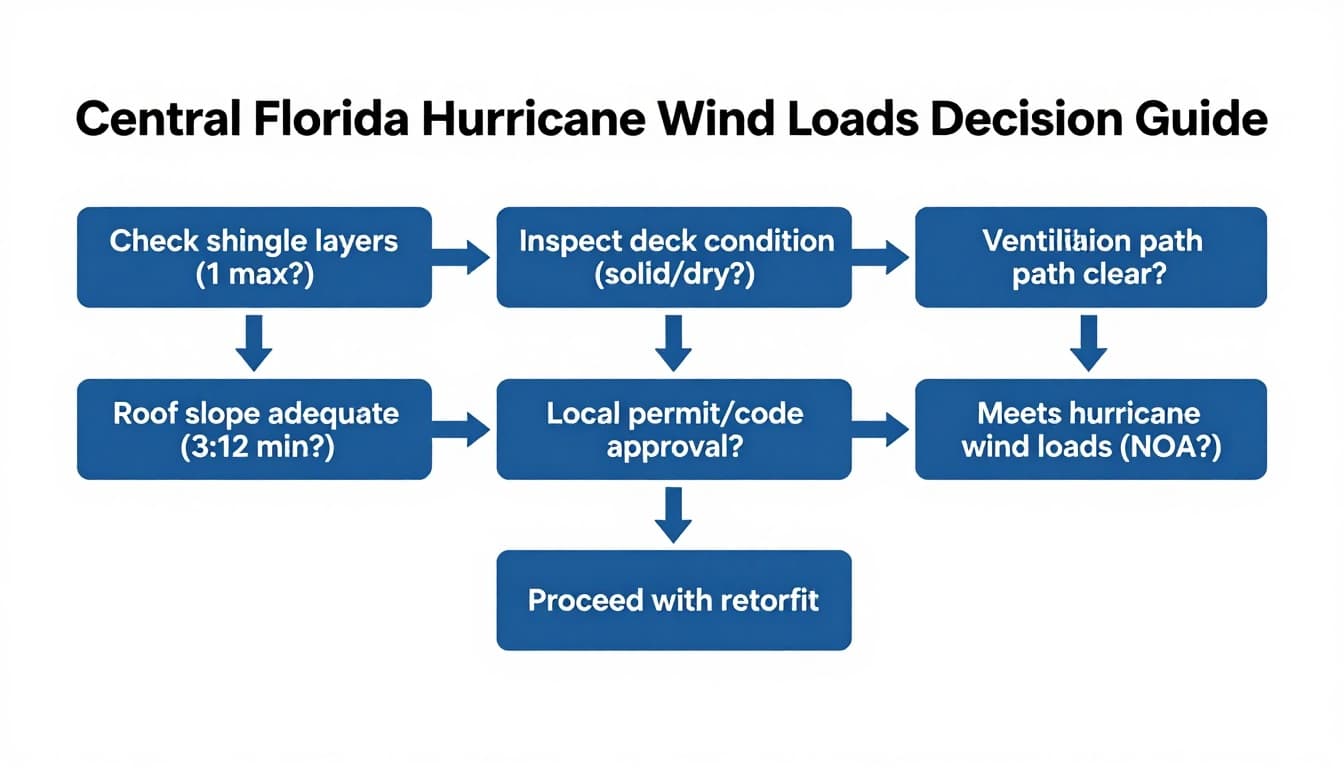

Simple decision flow for choosing overlay vs. tear-off with Florida wind and permit realities, created with AI.

Simple decision flow for choosing overlay vs. tear-off with Florida wind and permit realities, created with AI.

Overlay usually saves on tear-off labor and disposal , and it can shorten the job. The risk is paying later for what you didn’t uncover: hidden deck damage, old flashing shortcuts, or moisture that stays trapped because airflow details weren’t rebuilt.

Tear-off costs more up front, but it buys you certainty. You can replace bad sheathing, re-nail or upgrade deck fastening where required, rebuild valleys cleanly, and start the metal system on a flat, known surface. That can matter for resale and for insurance conversations, since documentation and permit closure help.

One more point that shouldn’t be optional: pull permits . Florida roofing work is heavily inspected for a reason, and DIY metal roofing is hazardous. Falls happen fast, and hurricane-rated assemblies aren’t forgiving of “close enough.” If wind-load design or unusual geometry is involved, ask for an engineer or qualified contractor evaluation so the fastener schedule and uplift details match the real pressures on your home.

Conclusion

A metal roof retrofit over shingles can be a smart move in Central Florida when the roof has one flat shingle layer, a dry solid deck, verified ventilation, and an approved uplift-rated assembly installed exactly to spec. It’s a bad bet when you’re covering curled shingles, weak decking, multiple layers, or flashing problems you can’t fully rebuild.

If you’re on the fence, treat it like a medical scan: verify what’s underneath first, then choose overlay or tear-off based on facts, permits, and wind-load requirements.

Share Our Metal Roofing News Articles

Related Posts

Florida Product Approval and Miami-Dade NOA for Metal Roofing, how to pick compliant panels and trim