Standing Seam Clip Spacing Guide For Central Florida Wind Loads

If a standing seam roof fails in a Florida wind event, it usually doesn't start in the middle of the roof. It starts where the wind pulls hardest: corners, edges, and transitions.

That's why standing seam clip spacing matters so much in Central Florida. Clip layout is one of the few parts of the roof you can't "eyeball" later. Once panels are locked and trimmed out, spacing is baked in.

Safety and liability note: Don't use this as a universal clip schedule. Final clip type, fastener type, and spacing must match the exact tested/engineered panel system (uplift tables, Florida Product Approval, Miami-Dade NOA if applicable) and the project's calculated design pressures. For higher exposures, near-coastal conditions, or any HVHZ work, involve the manufacturer and a Florida-licensed engineer .

What clip spacing really controls (and what it doesn't)

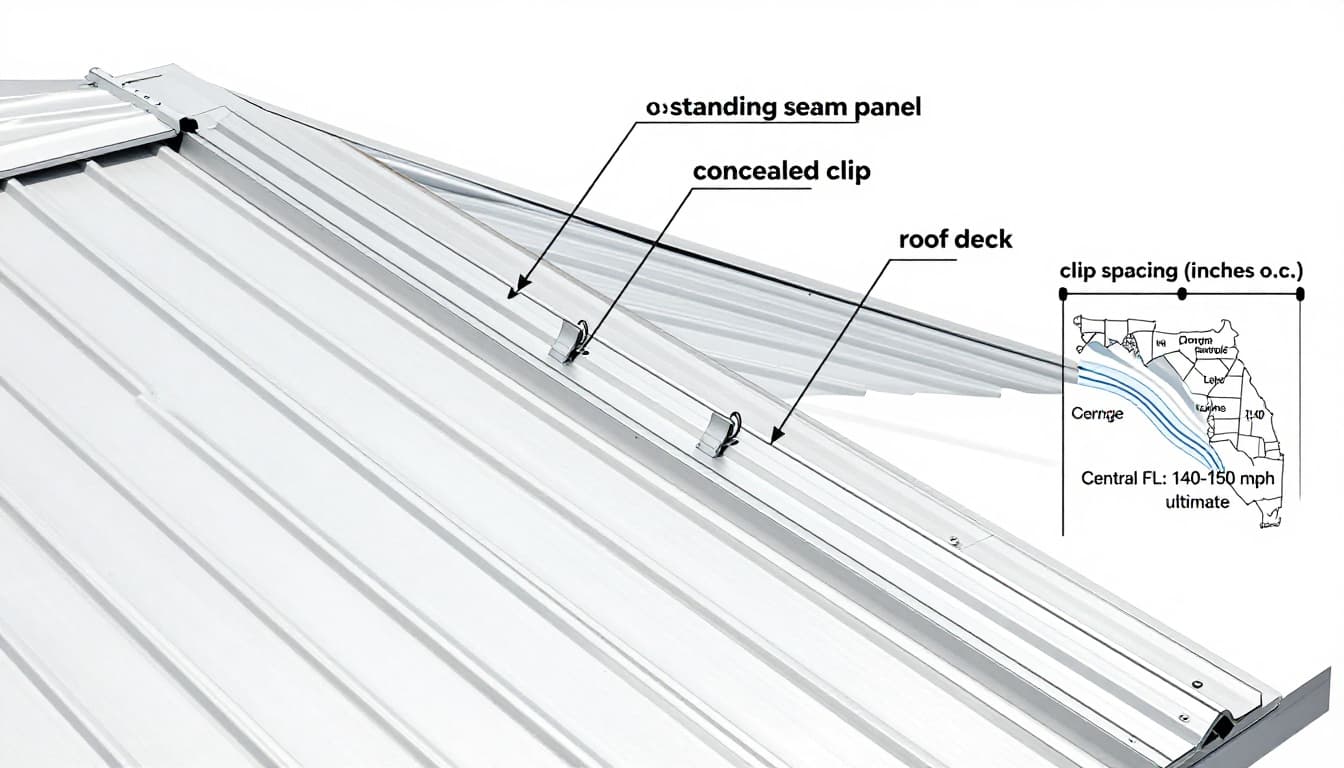

Cutaway view of a typical concealed-clip standing seam assembly and an example clip spacing callout (diagram created with AI, wind contour numbers shown are illustrative only).

Cutaway view of a typical concealed-clip standing seam assembly and an example clip spacing callout (diagram created with AI, wind contour numbers shown are illustrative only).

Think of clips like fence posts. The panel is the fence rail. If the posts are too far apart, the rail flexes and the connections take a beating.

Clip spacing affects three practical things on real jobs:

First, it controls uplift resistance . More clips (and more fasteners into the deck) usually increases allowable negative pressure, but only when the tested assembly says it does. Some systems "cap out" because the seam, clip, or panel flange becomes the weak link.

Second, it helps limit panel flutter and oil canning triggers . Wide spacing can let the pan flex more under gusts. That doesn't always cause leaks, but it can show up as noise, movement, or visible distortion. Clip choice matters here, not just spacing. (Fixed clips vs floating clips behave differently.)

Third, it manages thermal movement . Central Florida sun loads are no joke. If you tighten spacing without using the clip type intended for movement, you can trade uplift strength for panel stress, fastener wallowing, or seam distortion.

On the other hand, clip spacing does not fix these common problems:

- Bad perimeter metal (under-designed fascia, rake, or inadequate continuous cleats).

- Wrong underlayment strategy for wind-driven rain.

- Deck attachment issues (weak sheathing nailing, rotten decking, missed trusses).

- Mix-and-match parts (clips and fasteners that aren't part of the approved assembly).

If you need a quick refresher on how the whole roof system works together, this overview of hurricane-ready metal roof components ties clips, edges, and underlayment into one picture.

Florida code and approvals in February 2026: what estimators should verify

Florida is code-driven, but the paperwork is only useful if it matches the exact system on the roof.

As of February 2026, the Florida Building Code 8th Edition (2023) is in effect statewide, and the 9th Edition (2026) is scheduled to take effect later in 2026. Wind design still runs through the FBC wind provisions and the referenced ASCE 7 standard in the adopted code. Your permit set and jurisdiction tell you which referenced edition applies to that project.

From an estimating and submittal standpoint, clip spacing should flow from three checkpoints:

-

Calculated design pressures for the building (Field, Perimeter, Corners). These come from the project wind design, exposure, height, roof geometry, and internal pressure assumptions.

-

The panel system's tested uplift tables , which translate pressure into allowed spans and clip spacing. These tables also call out clip models, fastener types, and substrate limits.

-

Florida's approval pathway. Most metal roof systems need a Florida Product Approval number, and in Miami-Dade or Broward they often need a Miami-Dade NOA.

For approvals research, the state portal is the fastest "source of truth." Start with the Florida Product Approval search. If you want an easier way to view approval documents in one place, directories like Engineering Plans Florida approvals can help you preview what a complete listing looks like (still confirm details on the official portal).

For a plain-English rundown of what Florida expects from metal roofing systems, keep this handy: Florida metal roofing building codes.

Zone-by-zone clip spacing strategy (Field, Perimeter, Corners)

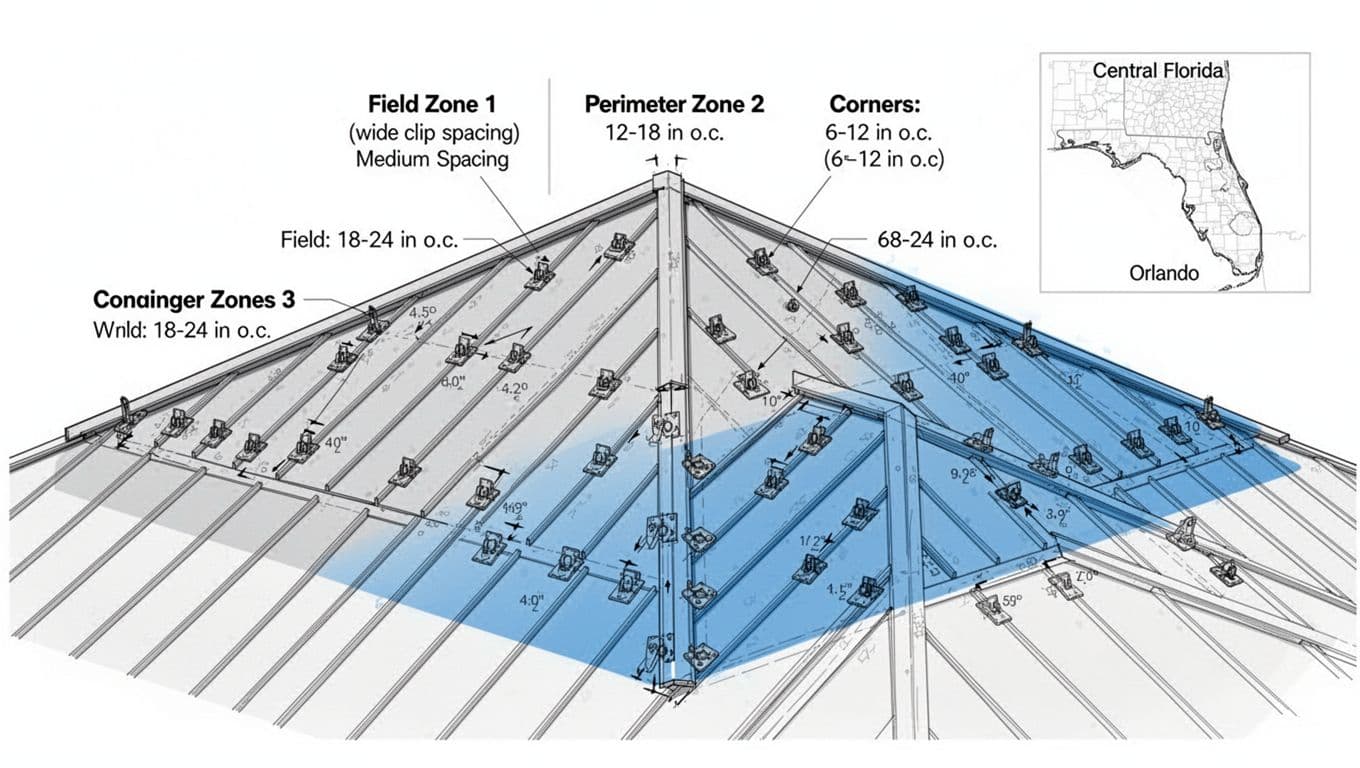

Simple zone map showing why clip spacing tightens as you move toward edges and corners (diagram created with AI).

Simple zone map showing why clip spacing tightens as you move toward edges and corners (diagram created with AI).

Most Central Florida roofs should be treated like three different roofs. The field might be forgiving. The corners won't be.

Here's the practical way to build a clip schedule from uplift tables: start at corners, then perimeters, then field. If the corners demand tighter spacing or a heavier clip, don't "average it out." Corners drive failures.

One short table helps crews and inspectors stay aligned. Treat these ranges as examples only, because every standing seam system tests differently.

| Roof zone | What wind is trying to do | Example clip spacing range (illustrative only) | What to verify in uplift tables |

|---|---|---|---|

| Field (Zone 1) | Lift panels evenly | 18 to 24 inches o.c. | Panel gauge, clip model, deck type, screw embedment |

| Perimeter (Zone 2) | Pry at the edges | 12 to 18 inches o.c. | Edge metal details, first clip location, seam type |

| Corners (Zone 3) | Concentrate suction and peel | 6 to 12 inches o.c. | Corner coefficients, clip capacity, fastening pattern |

The takeaway is simple: clip density increases as you approach edges and corners, because wind pressures rise sharply there.

Two job-site details get missed often:

- First clip placement at eaves and ridges : Many systems require the first clip closer than "typical spacing." That prevents seam rotation at the starting edge.

- Transitions and penetrations : Pipe curbs, skylights, and wall transitions can create local turbulence. Some manufacturers call for added clips near these details, even inside the field zone.

Corner zones: where spacing mistakes show up first

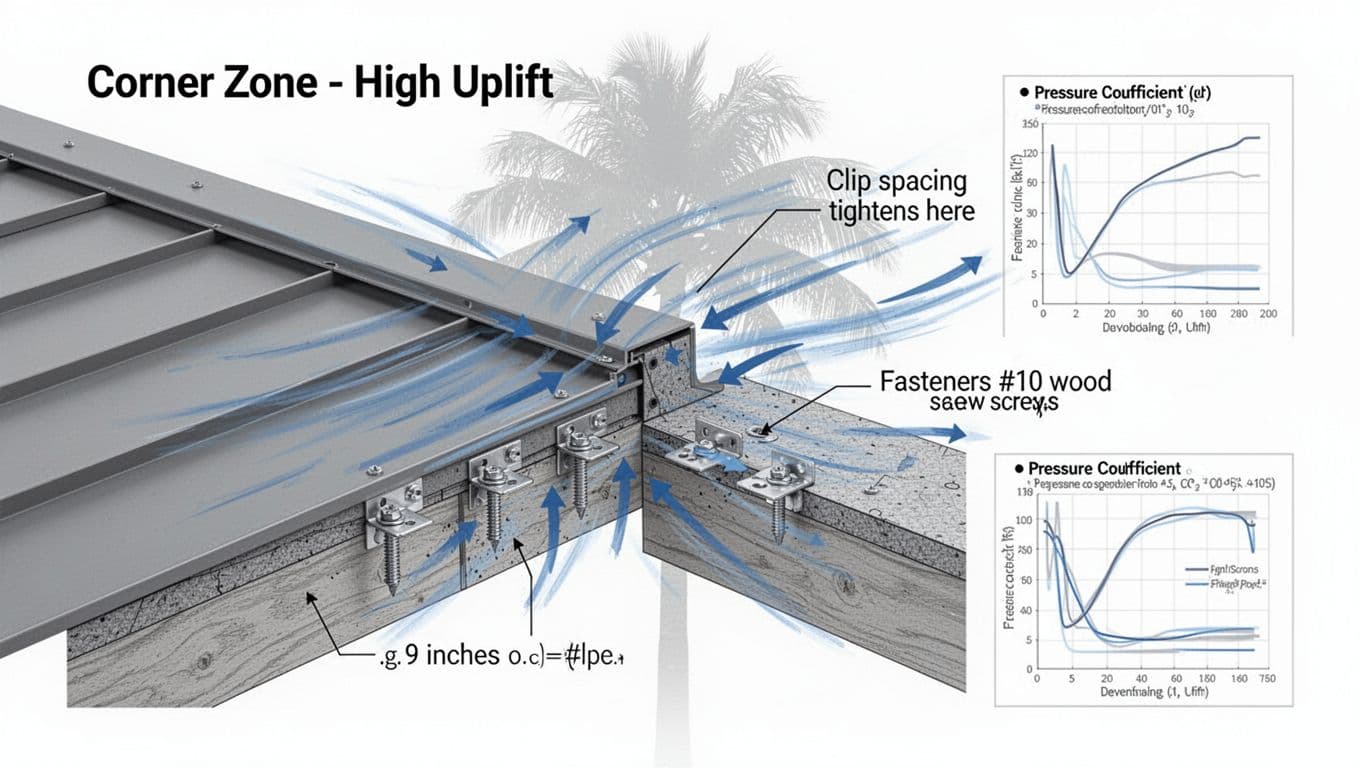

Corner-zone uplift concentrates at the roof edge, so clip spacing and fastener choice matter most here (diagram created with AI).

Corner-zone uplift concentrates at the roof edge, so clip spacing and fastener choice matter most here (diagram created with AI).

Corners act like a hand peeling tape off a box. The wind doesn't just lift, it tries to unzip the seam and walk the panel.

Because of that, corner detailing should be treated as its own scope line in your estimate. Besides tight standing seam clip spacing, pay attention to:

Clip type : Some assemblies require a higher-capacity clip in perimeter and corners, not just tighter spacing. Swapping clip models can also change screw requirements.

Fastener schedule into the deck : Uplift tables often assume a specific screw size, thread type, and minimum embedment. If the deck is old, patched, or uneven, call it out before install day.

Edge metal attachment : A strong panel system can still fail if the perimeter metal flutters. If the approval requires a continuous cleat, treat it as required, not optional.

If you're guessing in corners, you're gambling. Corners don't forgive "close enough."

Estimating and submittal tips that prevent clip schedule surprises

Clip schedules go sideways when the scope doesn't match the testing. A few habits keep you out of trouble:

Start by confirming the exact panel profile (snap-lock vs mechanical seam), panel gauge, seam height, and clip type. Even within "standing seam," approvals vary a lot. If the owner is still choosing profiles, point them to this introduction to standing seam panels so expectations match reality.

Next, verify the substrate . A roof over plywood behaves differently than one over purlins. Uplift tables are substrate-specific, and so are fasteners.

Finally, document your assumptions. A clean note in your proposal can prevent a change order fight later, for example: "Clip spacing per manufacturer's uplift table for calculated pressures, field/perimeter/corners vary."

If you need one quick "sanity check," it's this: when a job moves from a sheltered inland subdivision to a more open site, clip density often climbs, especially at edges. The roof looks the same, but the wind exposure doesn't.

Conclusion

Standing seam roofs do great in Central Florida, but only when the attachment plan matches the wind pressures. The right standing seam clip spacing isn't a single number, it's a zone-based schedule tied to approvals and uplift testing. Start with corners, confirm the exact system, and write your assumptions down. When the site exposure is higher or the project touches HVHZ rules, bring in the manufacturer and a Florida-licensed engineer so the roof you price is the roof that gets approved.