Metal Roof Underlayment Fastener Patterns in Florida, Cap Nails vs. Staples, Spacing, and Leak Risk

If a metal roof leak shows up, people often blame the panels. In Florida, the real trouble sometimes starts under the panels, with metal roof underlayment fasteners that were spaced wrong, driven wrong, or simply the wrong type.

Underlayment is your roof's backup raincoat. During a thunderstorm, or when a job gets "dried in" before panels go on, it can be the only thing between your decking and water. That's why fastener choice and pattern matter so much for homeowners, contractors, and adjusters.

Why Florida cares so much about underlayment fastening

Florida roofs live through wind-driven rain, daily heat swings, and hurricane season. That combination pushes water sideways and upslope, then tests every puncture in the underlayment.

The Florida Building Code focuses on keeping the underlayment attached and watertight enough to do its job. For the current code language and related roof assembly requirements, start with Florida Building Code Chapter 15. In many common mechanically attached underlayment approvals, you'll see patterns that tighten at laps and edges, because those are the first places wind and water try to get under.

A few definitions help keep everyone on the same page:

- o.c. spacing : "On center", the distance from one fastener to the next.

- Field : The main flat area of the sheet, away from overlaps.

- Lap : Where one sheet overlaps another (side laps and head laps).

- Capillary action : Water "wicking" through tiny gaps, including around punctures.

If the underlayment looks like a drum skin in the wind, the fastener pattern is part of the fix, not an afterthought.

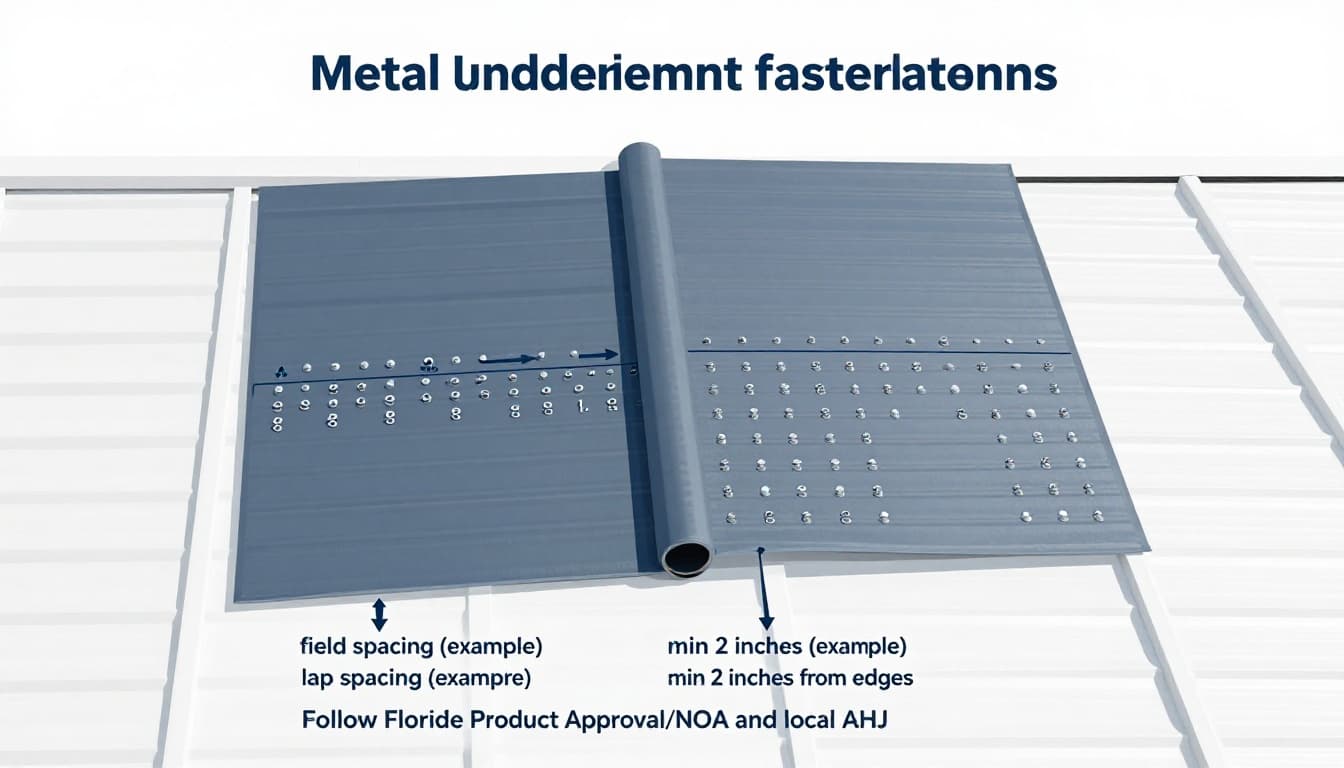

For Florida projects, don't guess. Always defer to the specific underlayment's Florida Product Approval or Miami-Dade NOA, plus the local AHJ (Authority Having Jurisdiction). If you need a quick refresher on underlayment types used under metal, see metal roof underlayment options for Florida homes.

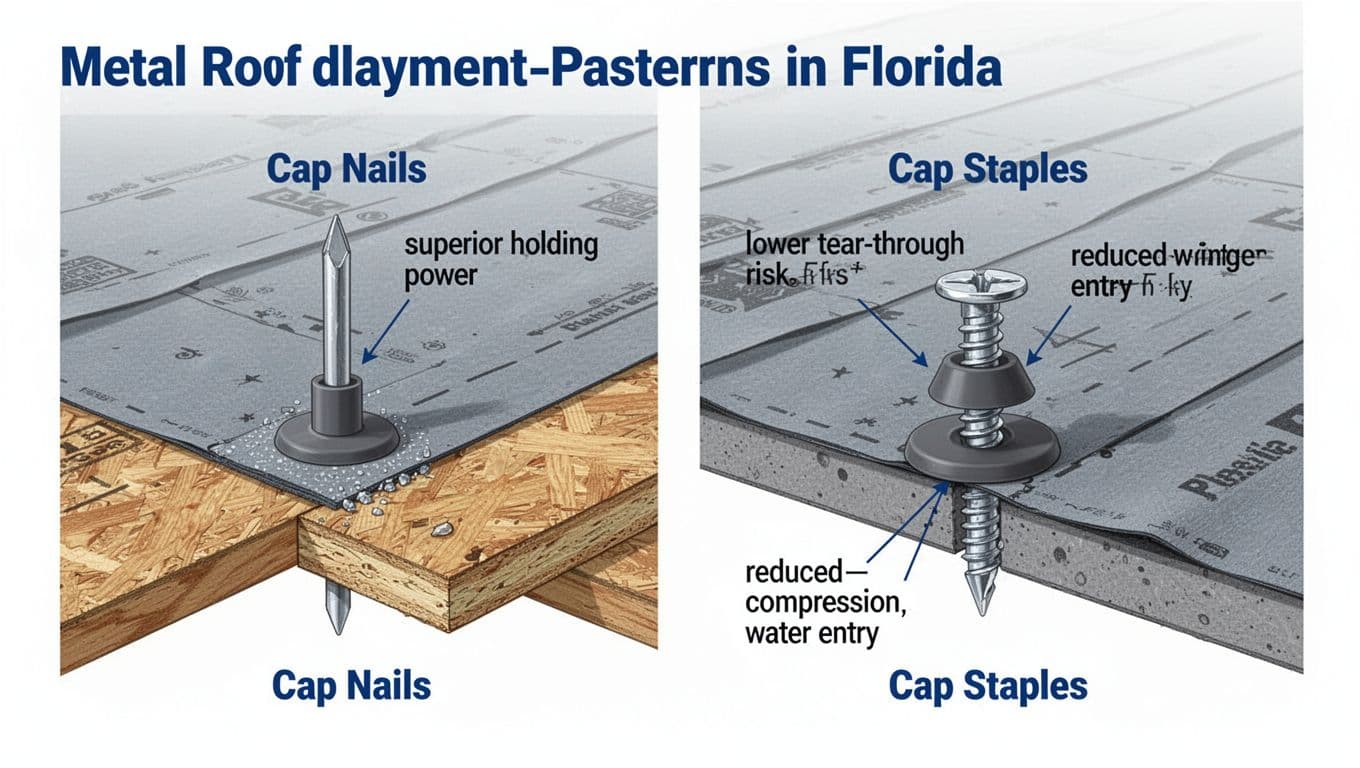

Cap nails vs. staples: what they are, and why caps change the outcome

Side-by-side look at how a cap spreads load over the underlayment, created with AI.

Side-by-side look at how a cap spreads load over the underlayment, created with AI.

Here are the fastener terms you'll hear on Florida job sites:

- Cap nail : A nail driven through a plastic or metal cap (usually about 1 inch diameter or larger). The cap spreads the load and helps seal the puncture area.

- Cap staple : A staple driven with a cap under the crown, so the cap clamps the underlayment.

- Crown staple (no cap) : A standard staple. Even if it "holds" today, it can slice or tear underlayment when wind lifts and flutters the sheet.

Florida code language and many approvals call for corrosion-resistant fasteners, and commonly require cap nails or cap staples , not bare staples. Manufacturer documents can also summarize Florida acceptance paths, for example GAF's underlayments guidance for Florida codes and HVHZ.

A practical rule: caps reduce failure in two ways. First, they reduce tear-through when the sheet flaps. Second, they help limit water entry at the puncture by compressing more surface area.

Here's a quick comparison for decision-making and inspections:

| Fastener option | What it is | Strengths | Common failure modes | Typical Florida fit (depends on approval) |

|---|---|---|---|---|

| Cap nails | Nail with plastic or metal cap | Consistent holding, good tear resistance | Overdriven caps, angled nails, missed framing | Widely accepted for mechanically attached underlayments |

| Cap staples | Staple with cap | Fast install, good clamp area | Crooked staple legs, under-driven caps | Accepted when approval allows, must meet gauge and cap specs |

| Crown staples (no cap) | Standard staple only | Cheap, fast | Slices sheet, tears at flutter points | Often rejected by approvals, higher leak and blow-off risk |

Fastener durability matters too. Corrosion and seal washer failures can create leaks later, even with a great panel install. For exposed fastener systems and long-term performance, review the importance of long-life metal roof fasteners Florida.

Example spacing patterns (field vs. lap) and where leak risk really starts

Example fastener grid showing tighter spacing at laps, created with AI.

Example fastener grid showing tighter spacing at laps, created with AI.

Spacing is where good installs separate themselves. Too wide, and the sheet flutters, tears, and opens laps. Too tight in the wrong place, and you "stitch" water pathways near overlaps.

Example only (not a universal spec): Many Florida-approved mechanically attached underlayments use a grid that's tighter at the lap than in the field, such as 6 inches o.c. along laps and 12 inches o.c. in the field . Some systems call for double rows at laps. Others require different patterns at edges, corners, or high-wind zones. Always follow the specific Florida Product Approval or NOA, plus AHJ instructions.

So how do leaks actually happen at underlayment fasteners?

- Capillary action at punctures : A tiny gap at a nail shank can wick water, especially when wind keeps the surface wet.

- Fasteners too close to lap edges : Water runs across the lap line, then finds punctures sitting in the "wet zone."

- Fishmouths and wrinkles : A fishmouth is a raised ridge at a lap or overlap. It creates a tunnel that wind-driven rain can ride.

- Overdriven fasteners : When the cap crushes or cuts the underlayment, you lose clamp force and create a tear point.

- Torn underlayment around fasteners : Flutter plus poor spacing turns small holes into long slits.

HVHZ details can add another layer of scrutiny. Miami-Dade often publishes guidance and change summaries, including presentations like HVHZ roofing code changes for the 2023 FBC. Even outside HVHZ, inspectors may look closely at underlayment attachment if the roof is left exposed before metal panels go on.

Jobsite verification checklist (contractors, homeowners, and adjusters)

A fast walk-through can catch most underlayment fastening problems before panels hide them. Use this as a field check, then confirm against the product approval and AHJ requirements.

- Correct fastener type : Cap nails or cap staples match the underlayment approval, no bare crown staples unless allowed.

- Cap condition : Caps sit flat, not cracked, not cupped, and not cutting into the sheet.

- Drive quality : Fasteners are perpendicular, not angled, and not under-driven.

- Spacing matches the approval : Field and lap patterns follow the published schedule, with tighter laps where required.

- Laps look "shingled" : Overlaps shed water downslope, with no reverse laps.

- No fishmouths : Wrinkles are slit and patched per manufacturer instructions, not ignored.

- Edge and penetration details : Valleys, transitions, and pipe boots follow the approved method.

- Temporary dry-in readiness : If weather's coming, confirm the underlayment is tight enough to resist uplift.

Safety note: roof work is dangerous in Florida heat and sudden rain. Use fall protection, watch for slick underlayment, and don't work when winds pick up.

For a broader materials cross-check before the job starts, keep Central Florida underlayment and fasteners guide handy.

Conclusion

Underlayment fastening is easy to overlook because it disappears under metal panels. Still, metal roof underlayment fasteners and their patterns can decide whether wind-driven rain stays outside or finds a path in. Choose cap fasteners, drive them cleanly, and match spacing to the specific Florida Product Approval or NOA and the AHJ. When the next storm hits, the best leak prevention is the work nobody sees.