The Truth Behind the Material

We Stand Behind Our Material

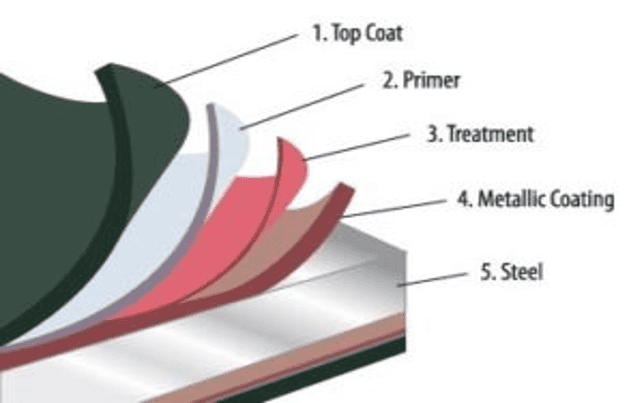

Mid Florida Metal Roofing Supply is committed to using only the highest quality products for our panel systems. Our products are made of the highest quality steel, allowing us to provide top quality material to our customers. The lifespan of a steel roof or wall panels depends on the quality of the coating system that protects it.

Inferior coatings used by other manufacturers will not protect the steel substrate from the harsh elements and will be susceptible to corrosion, excessive chalking and faster color fading. Some manufacturers only subject their coating systems to “simulated” accelerated weathering tests, which do not yield the same accurate and reliable results as real-world testing.

Our coated material proves its ability to hold up to continuous and long-term exposure to the sweltering sun and high humidity of Florida.

The same high-performance pigments that resist color change are also designed to reflect the sun’s solar energy before it can be absorbed as heat, keeping the metal roof cooler than traditional roofs. The infrared reflective pigments can lower roof surface temperature by up to 100˚F. The result is a building that stays cooler and reduces energy use. All standard colors are ENERGY STAR® rated.

Our Materials, Put to the Test

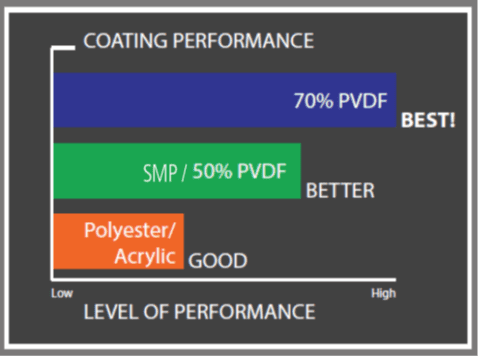

Coating Performance

Exposure to the sun (UV light), moisture and humidity, high temperatures and temperature fluctuations can lead to color changes, chalking blistering corrosion and many other physical factors to the protective metal coating.

There are two key approaches to weather testing: long term natural exterior weather exposure and laboratory accelerated weathering. Each of these testing approaches verifies performance, application, weathering and appearance of our sample panels.

Test and evaluations are performed to appropriate industry association standards by Valspar technical experts.

Natural Exposure

Exterior weather exposure (natural weathering) involves placing sample panels on inclined open racks orientated at the sun, usually at a 45° angle in southerly direction. This angle ensures full UV exposure. (Shown above)

Accelerated Exposure

Special environmental cabinets and instruments are used to speed up the weathering process and measure its effects under extreme conditions.

Testing Standards

What is ASTM?

ASTM International, formerly known as the American Society of Testing and Materials (ASTM), is a globally recognized leader in the development and delivery of internal voluntary consensus standards. ASTM standards help level the playing field so that businesses of all sizes can better compete in the global economy. *www.astm.org

What is AAMA?

American Architectural Manufacturers Association (AAMA) stands as a strong advocate for manufacturers and professionals in the fenestration industry and dedicated to the promotion of quality window, door, curtain wall, storefront, and skylight products. They work to improve product, material and component performance standards. *www.aamanet.org

Other Associations

We’re in good company when it comes to our Green Agenda. Because when you’re a proud member of the following organizations, sustainability becomes top priority; Energy Star, USGBC (U.S. Green Building Council) and LEED and CRRC (Cool Roof Rating Council).

The Coating Process

Valspar is the leader in coil and extrusion coatings. Both are protective coatings that are applied in an automated process.

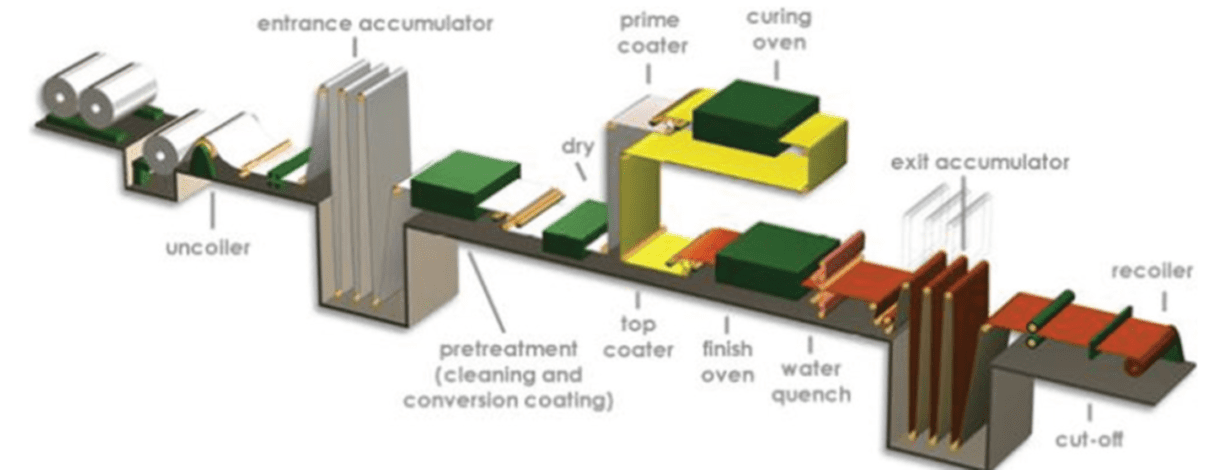

Coil: Continuous Coil

Coil coating are applied to coil formed metal sheets by a continuous, automated process that can happen at up to 700 feet per minute. Coil is unwound, cleaned, treated, primed, painted, and baked before being recoiled for shipment.

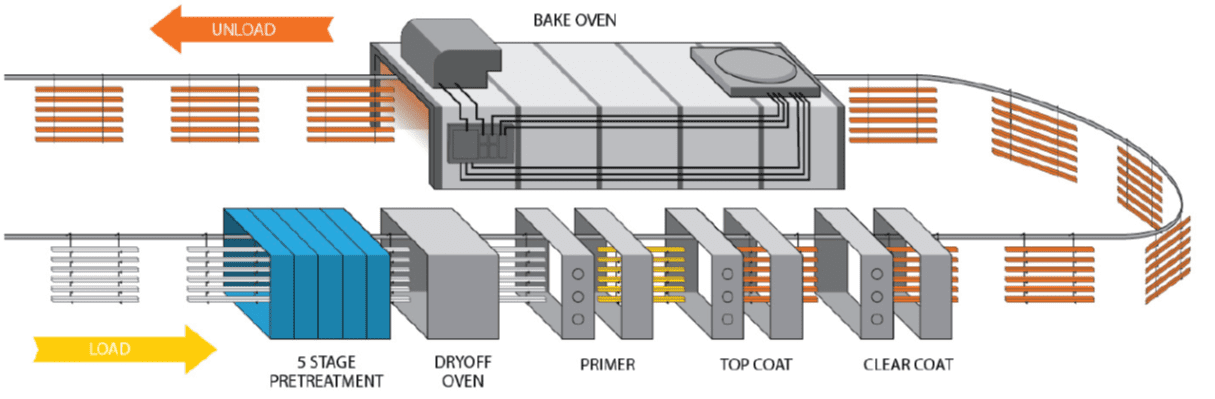

Extrusion: Horizontal or Vertical Lines

Extrusion coatings are applied in a manufacturing process that consists of cleaning pretreating aluminum preformed extrusions, through a spray process, and then thermally curing the coating to set the system.

What is Coating?

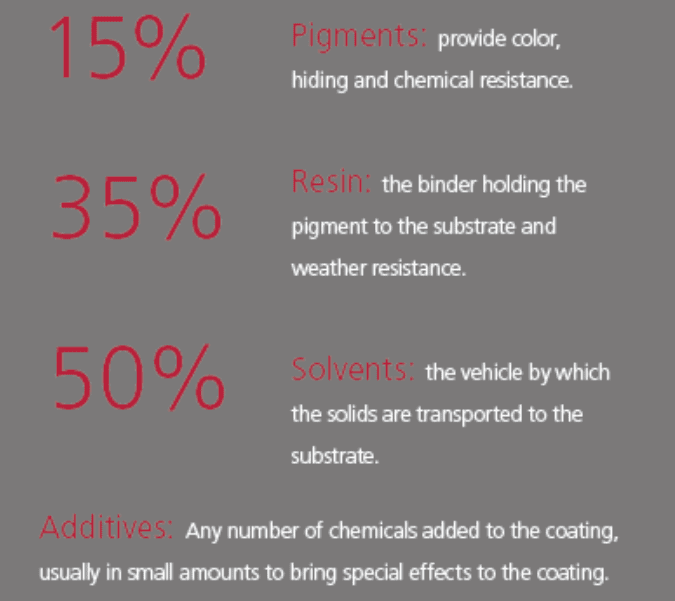

Coating is comprised of four principal ingredients: resin, pigment, solvent, and additives. The percentage of each item can change depends on the coatings final application and color.

One key ingredient can make or break a coating and that is pigments, which provide the coatings color and function. The pigment component of any formulation can either enhance or degrade the overall performance of the protective color coating.

Pigments are added to paint to provide color and can be blended to create a desired color to suite the aesthetics of an application.

Organic Pigments: Natural very bright appearance but have a low resistance to fade. Poor weathering.

Inorganic (ceramic) Pigment: Made of metal oxides and mixed metal oxides that have high resistance to fade. Excellent weathering.

Resin Types

The primary function of resin is to act as the binder in a paint formulation by binding all of the components together. It is the source for a coatings’ durability and physical properties. It increases the physical strength and chemical resistance of the coating film and allows for the curing process to occur while paint is drying.

Our Commitment to Quality

Mid Florida Metal Roofing Supply stands behind our products and we have the support of some of the best material suppliers in the business. We offer warranties for all of our panel systems. However, over our 16 years of manufacturing roof and wall panels, we have had NO warranty claims.

For information or questions on our warranties visit https://midfloridametalroofingsupply.com/warranties/ or contact your sales representative at 352-742-7070

About Mid-Florida Metal Roofing

Mid-Florida Metal Roofing Supply has been in the business for 16 years. MFMRS manufactures a wide variety of metal roofing products including; Multi-Rib (AG), PBR/R, 5V and Standing Seam in a Galvalume mill finish, as well as, a wide variety of colors to meet all your preferences.

We also manufacture an extensive list of flashing profiles to meet any standard or custom application as needed. We specialize in custom profiles serving a wide variety of needs in the construction industry. Our profiles can also be ordered in custom lengths up to 21ft.

We are committed to producing quality products in a timely manner and pride ourselves with friendly personal customer service.